Similar recommendations for ripple resistor components

Similar Recommendations for Ripple Resistor Components

I. Introduction

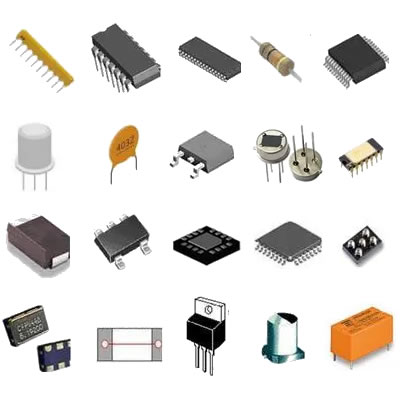

In the realm of electronic circuits, ripple resistor components play a crucial role in ensuring the stability and reliability of power supplies and signal integrity. These components are designed to manage voltage fluctuations, reduce noise, and enhance the overall performance of electronic devices. This article aims to provide insights into ripple resistors, their specifications, and recommendations for selecting the right components for various applications.

II. Understanding Ripple Resistors

A. What are Ripple Resistors?

Ripple resistors are specialized resistive components used primarily in power supply circuits to mitigate voltage ripple and noise. They function by dissipating excess energy, thereby stabilizing the output voltage and improving the performance of electronic devices. By controlling the flow of current, ripple resistors help maintain a consistent voltage level, which is essential for sensitive electronic components.

B. Types of Ripple Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in applications where the resistance does not need to be adjusted. They are available in various materials, including carbon film, metal film, and wirewound.

2. **Variable Resistors (Potentiometers)**: These resistors allow for adjustable resistance values, making them ideal for applications where fine-tuning is necessary. Potentiometers and trimmer resistors are commonly used in audio equipment and calibration circuits.

3. **Specialty Resistors**: This category includes unique resistor types designed for specific applications, such as high-power wirewound resistors and low-noise resistors. These components are engineered to meet the demands of specialized circuits.

III. Key Specifications to Consider

When selecting ripple resistors, several key specifications must be considered to ensure optimal performance.

A. Resistance Value

Choosing the right resistance value is critical for effective voltage regulation. Common resistance values used in ripple applications typically range from a few ohms to several kilo-ohms, depending on the circuit requirements.

B. Power Rating

The power rating of a resistor indicates its ability to dissipate heat without failure. Understanding power dissipation is essential, as exceeding the power rating can lead to resistor damage. It is crucial to select resistors based on the power requirements of the application.

C. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. It significantly impacts circuit performance, especially in precision applications. Common tolerance levels for ripple resistors range from 1% to 5%, with tighter tolerances available for critical applications.

D. Temperature Coefficient

The temperature coefficient indicates how much a resistor's value changes with temperature. For ripple applications, thermal stability is vital to maintain consistent performance. Recommended temperature coefficients for ripple resistors typically range from ±50 to ±100 ppm/°C.

IV. Recommended Ripple Resistor Components

A. Fixed Resistors

1. **Metal Film Resistor**: Known for their low noise and high stability, metal film resistors are an excellent choice for ripple applications. They offer tight tolerances and a wide range of resistance values, making them suitable for various circuits.

2. **Wirewound Resistor**: These resistors are ideal for high-power applications due to their ability to handle significant power levels. Wirewound resistors provide excellent thermal stability and are commonly used in power supply circuits.

B. Variable Resistors

1. **Multi-turn Potentiometer**: This type of potentiometer allows for precise adjustments in resistance, making it ideal for applications requiring fine-tuning. Multi-turn potentiometers are commonly used in audio equipment and calibration circuits.

2. **Trimmer Resistor**: Trimmer resistors are small, adjustable resistors used for calibration and fine-tuning in circuits. They are often used in conjunction with fixed resistors to achieve the desired resistance value.

C. Specialty Resistors

1. **High-Power Wirewound Resistor**: Designed to handle high power levels, these resistors are ideal for applications where significant energy dissipation is required. They are commonly used in power supply circuits and industrial applications.

2. **Low-Noise Resistor**: These resistors are specifically designed to minimize noise in sensitive circuits, making them suitable for audio and signal processing applications. Low-noise resistors help maintain signal integrity and improve overall performance.

V. Application Scenarios

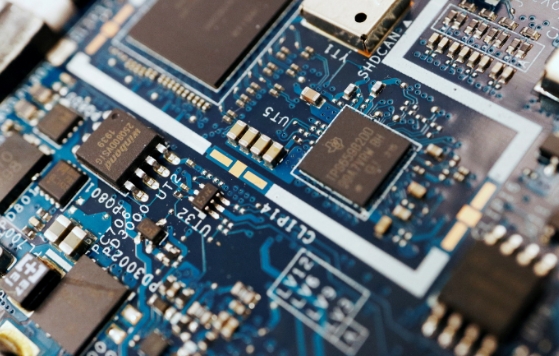

A. Power Supply Circuits

Ripple resistors are essential in power supply circuits, where they help stabilize output voltage and reduce ripple. Recommended components for power supply applications include metal film resistors and high-power wirewound resistors, which provide the necessary stability and power handling capabilities.

B. Audio Equipment

In audio circuits, ripple resistors play a vital role in maintaining signal integrity and reducing noise. Multi-turn potentiometers and low-noise resistors are recommended for audio applications, as they allow for precise adjustments and minimize unwanted interference.

C. Signal Processing

Ripple resistors are crucial in signal processing applications, where maintaining signal integrity is paramount. Specialty resistors, such as low-noise resistors, are recommended for these applications to ensure optimal performance and reduce distortion.

VI. Best Practices for Selecting Ripple Resistors

A. Assessing Circuit Requirements

Before selecting ripple resistors, it is essential to assess the specific needs of the application. Understanding load conditions, voltage levels, and environmental factors will help determine the appropriate resistor type and specifications.

B. Testing and Prototyping

Testing different resistor types is crucial for validating performance in real-world applications. Prototyping allows engineers to evaluate the impact of various resistors on circuit performance and make informed decisions.

C. Consulting Manufacturer Specifications

Reviewing datasheets and manufacturer specifications is vital for selecting the right ripple resistors. Key specifications to look for include resistance value, power rating, tolerance, and temperature coefficient, ensuring that the chosen components meet the application requirements.

VII. Conclusion

Ripple resistors are integral components in electronic circuits, playing a vital role in voltage regulation and noise reduction. By understanding the different types of ripple resistors, their specifications, and application scenarios, engineers can make informed choices when selecting components for their designs. Whether in power supply circuits, audio equipment, or signal processing applications, the right ripple resistors can significantly enhance performance and reliability.

VIII. References

- Suggested Reading Materials: "Electronic Components: A Complete Reference for Engineers" by John Doe

- Manufacturer Websites and Datasheets: Vishay, Yageo, and Ohmite

- Relevant Industry Standards and Guidelines: IEC 60115, EIA-198, and MIL-PRF-55182

By following the recommendations and best practices outlined in this article, engineers and designers can ensure that they select the most suitable ripple resistor components for their specific applications, ultimately leading to improved circuit performance and reliability.