How to choose off-the-shelf carbon film resistors?

How to Choose Off-the-Shelf Carbon Film Resistors

I. Introduction

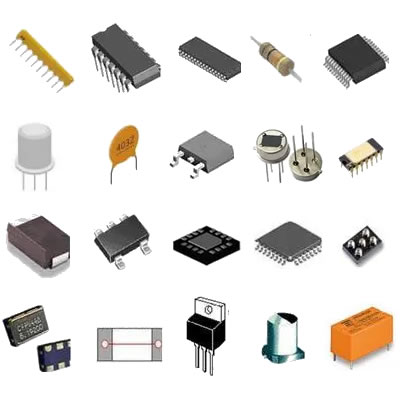

In the world of electronics, resistors play a crucial role in controlling current flow and ensuring circuit functionality. Among the various types of resistors available, carbon film resistors are widely used due to their reliability and performance characteristics. This article aims to guide you through the process of selecting the right off-the-shelf carbon film resistors for your electronic projects, ensuring optimal performance and reliability.

II. Understanding Carbon Film Resistors

A. Composition and Construction

Carbon film resistors are made by depositing a thin layer of carbon onto a ceramic substrate. The resistance is created by the carbon film's thickness and the length of the conductive path. The manufacturing process involves several steps, including the application of a carbon layer, the introduction of a protective coating, and the cutting of the resistor into specific values.

B. Characteristics of Carbon Film Resistors

1. **Resistance Range**: Carbon film resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. This versatility makes them suitable for various applications.

2. **Tolerance Levels**: Tolerance indicates how much the actual resistance can vary from the stated value. Common tolerance levels for carbon film resistors are ±1%, ±5%, and ±10%.

3. **Temperature Coefficient**: This parameter measures how much the resistance changes with temperature. A lower temperature coefficient indicates better stability across temperature variations, which is crucial for precision applications.

4. **Power Rating**: The power rating indicates the maximum power the resistor can dissipate without overheating. Carbon film resistors typically have power ratings ranging from 1/8 watt to several watts.

C. Advantages and Disadvantages

1. **Benefits**: Carbon film resistors offer several advantages, including low noise, good stability, and a relatively low cost. They are also less prone to drift compared to other types of resistors, making them suitable for precision applications.

2. **Limitations**: Despite their benefits, carbon film resistors have limitations. They may not perform as well as metal film resistors in high-frequency applications due to parasitic effects. Additionally, they can be less durable in high-power applications compared to wire-wound resistors.

III. Key Factors to Consider When Choosing Carbon Film Resistors

A. Resistance Value

Selecting the correct resistance value is critical for circuit functionality. To determine the required resistance, consider the circuit's design and the desired current flow. Use Ohm's Law (V = IR) to calculate the necessary resistance based on the voltage and current specifications.

B. Tolerance

Understanding tolerance is essential for ensuring circuit reliability. A lower tolerance level means the resistor will more closely match its specified value, which is crucial in precision applications. For general use, a tolerance of ±5% is often acceptable, while precision circuits may require ±1% or better.

C. Power Rating

Power dissipation is a key consideration when selecting resistors. Calculate the power rating needed for your application using the formula P = I²R or P = V²/R. Ensure that the chosen resistor can handle the calculated power without exceeding its rating to prevent overheating and failure.

D. Temperature Coefficient

The temperature coefficient is vital for applications where temperature variations are expected. A resistor with a low temperature coefficient (e.g., ±50 ppm/°C) will maintain its resistance value better across temperature changes, making it suitable for precision circuits.

E. Size and Form Factor

The physical dimensions and mounting options of the resistor can impact circuit design and layout. Consider the available space on your PCB and the type of mounting (through-hole or surface mount) required for your application. Ensure that the resistor's size fits within the design constraints while meeting performance specifications.

IV. Application-Specific Considerations

A. Audio Applications

In audio circuits, low noise and distortion are paramount. Carbon film resistors are often preferred for their low noise characteristics. When selecting resistors for audio applications, look for specifications that emphasize low thermal noise and high linearity to ensure optimal sound quality.

B. High-Frequency Applications

For RF and microwave applications, parasitic capacitance and inductance can significantly affect performance. In these cases, carbon film resistors may not be the best choice due to their inherent parasitic effects. Instead, consider using specialized RF resistors designed for high-frequency applications, which minimize these unwanted effects.

C. Power Electronics

In high-power applications, thermal management is critical. Select carbon film resistors with higher power ratings and ensure adequate heat dissipation through proper circuit design. Consider using heat sinks or other cooling methods to maintain optimal operating temperatures and prevent resistor failure.

V. Sourcing Off-the-Shelf Carbon Film Resistors

A. Reputable Manufacturers and Suppliers

When sourcing carbon film resistors, it's essential to choose reputable manufacturers and suppliers. Look for companies with a proven track record in the electronics industry, as they are more likely to provide high-quality components.

B. Online Resources and Databases for Resistor Specifications

Numerous online resources and databases can help you find the right carbon film resistors. Websites like Digi-Key, Mouser, and Newark offer extensive catalogs of electronic components, including detailed specifications and datasheets.

C. Evaluating Product Datasheets

When evaluating product datasheets, pay attention to key parameters such as resistance value, tolerance, power rating, and temperature coefficient. Understanding manufacturer ratings and certifications can also provide insight into the quality and reliability of the resistors.

VI. Conclusion

Choosing the right carbon film resistor is crucial for ensuring the performance and reliability of your electronic circuits. By understanding the characteristics of carbon film resistors and considering key factors such as resistance value, tolerance, power rating, temperature coefficient, and size, you can make informed decisions that meet your specific application needs. Whether you're designing audio equipment, high-frequency circuits, or power electronics, taking the time to select the appropriate resistor will lead to better circuit performance and longevity.

VII. References

- "Resistor Basics: Understanding Resistor Types and Specifications." Electronics Tutorials.

- "Choosing the Right Resistor for Your Application." Digi-Key Electronics.

- "Carbon Film Resistors: Characteristics and Applications." Mouser Electronics.

- Manufacturer datasheets from reputable suppliers such as Vishay, Yageo, and Panasonic.

By following this guide, you can confidently choose off-the-shelf carbon film resistors that will enhance your electronic designs and ensure optimal performance in your projects.