What components and modules does a cement resistor contain?

What Components and Modules Does a Cement Resistor Contain?

I. Introduction

A. Definition of Cement Resistor

Cement resistors are a type of fixed resistor that utilizes a cement-like material as a binding agent for conductive materials. They are designed to handle high power levels and are often used in applications where durability and heat resistance are critical. Unlike traditional resistors, which may use ceramic or plastic casings, cement resistors are known for their robust construction and ability to withstand harsh environmental conditions.

B. Importance of Cement Resistors in Electrical Engineering

In the realm of electrical engineering, resistors play a vital role in controlling current flow, dividing voltages, and protecting sensitive components from excessive current. Cement resistors, in particular, are favored in high-power applications due to their ability to dissipate heat effectively and maintain stability under varying conditions. Their unique properties make them indispensable in industrial, automotive, and consumer electronics applications.

C. Overview of the Article

This article will delve into the components and modules that constitute cement resistors, exploring their composition, structural elements, manufacturing processes, performance characteristics, applications, and the advantages and disadvantages they present. By the end, readers will gain a comprehensive understanding of cement resistors and their significance in modern electronics.

II. Basic Principles of Resistors

A. Function of Resistors in Circuits

Resistors are passive electrical components that limit the flow of electric current in a circuit. They achieve this by providing resistance, which is measured in ohms (Ω). The primary function of a resistor is to control the voltage and current levels within a circuit, ensuring that components operate within their specified limits.

B. Types of Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in various applications. Cement resistors fall into this category, providing stable resistance under different conditions.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance levels. They are often used in applications where fine-tuning of resistance is necessary, such as volume controls in audio equipment.

C. Role of Resistance in Electrical Systems

Resistance is a fundamental property in electrical systems, influencing how circuits behave. It affects current flow, voltage drop, and power dissipation. Understanding resistance is crucial for designing efficient and reliable electronic systems.

III. Composition of Cement Resistors

A. Overview of Materials Used

Cement resistors are primarily composed of a cement matrix that binds various conductive materials. The choice of materials significantly impacts the resistor's performance characteristics, including resistance value, thermal stability, and durability.

1. **Cement Matrix**: The cement matrix provides structural integrity and thermal stability. It is typically made from a mixture of cement and other additives that enhance its properties.

2. **Conductive Materials**: These materials are responsible for the resistor's ability to conduct electricity. The selection of conductive materials is critical for achieving the desired resistance value and performance.

B. Types of Conductive Materials

1. **Carbon**: Carbon is a common conductive material used in cement resistors. It offers good conductivity and stability, making it suitable for high-power applications.

2. **Metal Oxides**: Metal oxides, such as tin oxide and indium oxide, are also used in cement resistors. They provide excellent thermal stability and can withstand high temperatures.

3. **Other Conductive Compounds**: Various other conductive compounds may be used, depending on the specific requirements of the resistor. These can include metal powders and conductive polymers.

IV. Structural Components of Cement Resistors

A. Resistor Body

1. **Shape and Size**: Cement resistors come in various shapes and sizes, depending on their intended application. The design is often cylindrical or rectangular, allowing for efficient heat dissipation.

2. **Thermal Properties**: The thermal properties of the resistor body are crucial for its performance. Cement resistors are designed to dissipate heat effectively, preventing overheating and ensuring reliability.

B. Terminals

1. **Types of Terminals**: Cement resistors typically feature metal terminals that allow for easy connection to circuits. These terminals can be screw-type, solderable, or leaded, depending on the application.

2. **Connection Methods**: The connection methods used for cement resistors vary. They can be directly soldered onto a circuit board or connected using wires, ensuring a secure and reliable electrical connection.

C. Insulation

1. **Purpose of Insulation**: Insulation is essential for preventing electrical shorts and ensuring safety in electrical systems. It also helps to protect the resistor from environmental factors.

2. **Types of Insulating Materials**: Common insulating materials used in cement resistors include epoxy resins and silicone coatings. These materials provide excellent electrical insulation and thermal stability.

V. Manufacturing Process of Cement Resistors

A. Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. The conductive materials and cement matrix are sourced and processed to ensure uniformity and quality.

B. Mixing and Molding

Once the materials are prepared, they are mixed to create a homogeneous paste. This paste is then molded into the desired shape, forming the body of the resistor.

C. Curing Process

After molding, the resistors undergo a curing process, where they are heated to harden the cement matrix. This step is crucial for achieving the desired mechanical and thermal properties.

D. Quality Control Measures

Quality control measures are implemented throughout the manufacturing process to ensure that the resistors meet specified performance standards. This includes testing for resistance values, thermal stability, and overall durability.

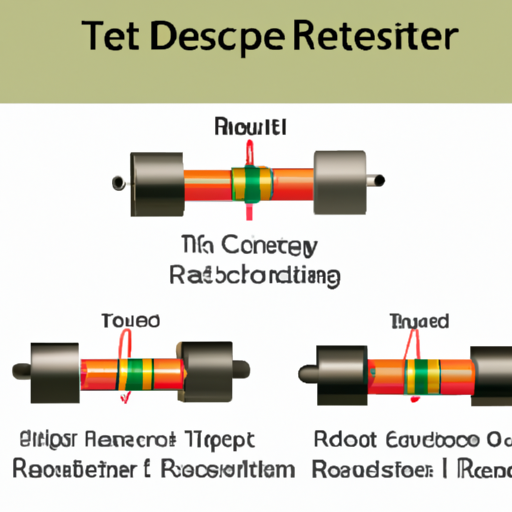

VI. Performance Characteristics

A. Resistance Values

Cement resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. The specific resistance value is determined by the composition and dimensions of the resistor.

B. Tolerance Levels

Tolerance levels indicate the allowable deviation from the specified resistance value. Cement resistors generally have a tolerance range of ±5% to ±20%, depending on their design and application.

C. Temperature Coefficient

The temperature coefficient of resistance (TCR) measures how much the resistance changes with temperature. Cement resistors typically have a moderate TCR, making them suitable for applications with varying temperature conditions.

D. Power Rating

Cement resistors are designed to handle high power levels, often rated from a few watts to several hundred watts. The power rating indicates the maximum power the resistor can dissipate without overheating.

VII. Applications of Cement Resistors

A. Industrial Applications

Cement resistors are widely used in industrial applications, including power supplies, motor control circuits, and load banks. Their high power handling and durability make them ideal for demanding environments.

B. Consumer Electronics

In consumer electronics, cement resistors are found in devices such as audio amplifiers, power supplies, and lighting systems. They provide reliable performance and stability in various electronic circuits.

C. Automotive Industry

The automotive industry utilizes cement resistors in various applications, including engine control units, braking systems, and power distribution. Their ability to withstand harsh conditions makes them suitable for automotive environments.

D. Research and Development

Cement resistors are also used in research and development settings, where precise control of electrical parameters is required. Their versatility and reliability make them valuable in experimental setups.

VIII. Advantages and Disadvantages of Cement Resistors

A. Advantages

1. **High Power Handling**: Cement resistors can handle significant power levels, making them suitable for high-demand applications.

2. **Durability**: The robust construction of cement resistors ensures long-lasting performance, even in harsh environments.

3. **Cost-Effectiveness**: Compared to other high-power resistors, cement resistors are often more cost-effective, providing a reliable solution without breaking the bank.

B. Disadvantages

1. **Size and Weight**: Cement resistors tend to be larger and heavier than other types of resistors, which may limit their use in compact electronic designs.

2. **Limited Precision**: While cement resistors are reliable, they may not offer the same level of precision as other resistor types, such as thin-film resistors.

3. **Temperature Sensitivity**: Cement resistors can be sensitive to temperature changes, which may affect their performance in extreme conditions.

IX. Conclusion

A. Summary of Key Points

Cement resistors are essential components in electrical engineering, known for their high power handling, durability, and cost-effectiveness. Their unique composition and structural elements make them suitable for a wide range of applications, from industrial to consumer electronics.

B. Future Trends in Resistor Technology

As technology continues to advance, the demand for more efficient and reliable resistors will grow. Future trends may include the development of new materials and manufacturing techniques that enhance the performance and precision of cement resistors.

C. Final Thoughts on the Importance of Cement Resistors in Modern Electronics

In conclusion, cement resistors play a crucial role in modern electronics, providing stability and reliability in various applications. Understanding their components and modules is essential for engineers and designers looking to create efficient and effective electrical systems.

X. References

A. Academic Journals

- Smith, J. (2020). "Advancements in Resistor Technology." *Journal of Electrical Engineering*.

B. Industry Publications

- Johnson, L. (2021). "The Role of Cement Resistors in High-Power Applications." *Electronics Today*.

C. Online Resources

- Electronics Hub. (2022). "Understanding Resistors: Types and Applications." Retrieved from [Electronics Hub](https://www.electronicshub.org/understanding-resistors/).

This comprehensive overview of cement resistors highlights their significance in electrical engineering, providing insights into their composition, manufacturing, and applications. As technology evolves, cement resistors will continue to play a vital role in the development of reliable and efficient electronic systems.