Latest Wirewound Resistor Specifications

Latest Wirewound Resistor Specifications

I. Introduction

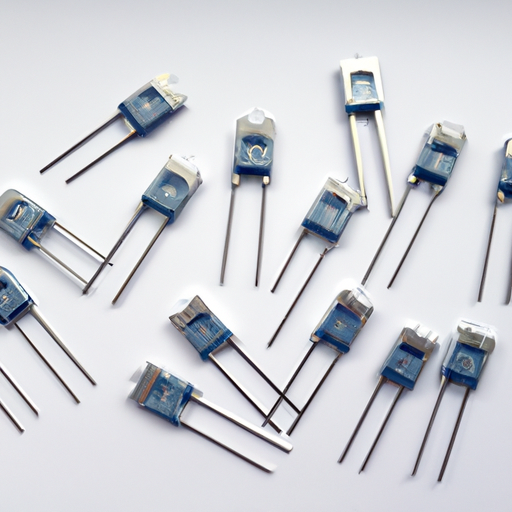

A. Definition of Wirewound Resistors

Wirewound resistors are a type of resistor that is constructed by winding a metal wire around a core. This design allows for precise resistance values and excellent performance in various applications. The wire is typically made from materials such as nickel-chromium or copper-nickel, which provide stability and reliability.

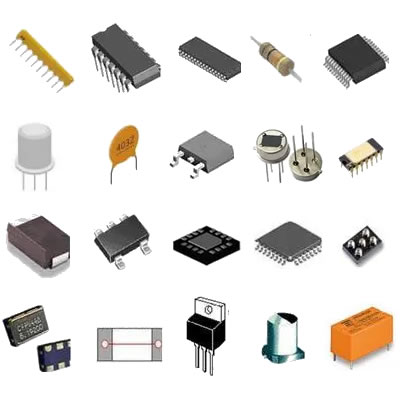

B. Importance of Wirewound Resistors in Electronic Circuits

Wirewound resistors play a crucial role in electronic circuits, serving as essential components for current limiting, voltage division, and signal conditioning. Their ability to handle high power and provide accurate resistance values makes them indispensable in both industrial and consumer electronics.

C. Purpose of the Article

This article aims to provide an overview of the latest specifications and advancements in wirewound resistors, highlighting their construction, performance characteristics, applications, and recent innovations.

II. Overview of Wirewound Resistors

1. Wire Types

The choice of wire material significantly impacts the performance of wirewound resistors. Common wire types include:

Nickel-Chromium (NiCr): Known for its high-temperature stability and resistance to oxidation, making it suitable for high-power applications.

Copper-Nickel (CuNi): Offers good conductivity and is often used in lower power applications.

2. Core Materials

The core material also affects the resistor's performance. Common core materials include:

Ceramic: Provides excellent thermal stability and is often used in high-power resistors.

Glass: Offers good insulation properties and is used in precision applications.

B. Working Principle

Wirewound resistors operate on the principle of Ohm's law, where the resistance is determined by the material's resistivity, the length of the wire, and its cross-sectional area. The winding of the wire around a core allows for a compact design while maintaining the desired resistance value.

1. Fixed Wirewound Resistors

These resistors have a predetermined resistance value and are widely used in various applications where a stable resistance is required.

2. Variable Wirewound Resistors (Potentiometers)

Variable wirewound resistors allow for adjustable resistance, making them ideal for applications such as volume controls in audio equipment.

III. Latest Specifications

1. Low Resistance Values

Recent advancements have expanded the range of low resistance values, with some wirewound resistors offering resistance as low as 0.1 ohms. These are particularly useful in current sensing applications.

2. High Resistance Values

On the other end of the spectrum, high resistance values can reach up to several megohms, catering to applications requiring precise voltage division.

1. Standard Power Ratings

Wirewound resistors are available in various power ratings, typically ranging from 0.25 watts to 100 watts. Standard power ratings are suitable for most general applications.

2. High-Power Applications

For high-power applications, specialized wirewound resistors can handle power ratings exceeding 1 kilowatt, making them ideal for industrial and automotive uses.

1. Standard Tolerances

Wirewound resistors are available with standard tolerances of 1% and 5%, which are adequate for many applications.

2. Precision Tolerances

For applications requiring higher accuracy, precision wirewound resistors with tolerances as low as 0.1% and 0.5% are available, ensuring minimal deviation from the specified resistance value.

1. Definition and Importance

The temperature coefficient of resistance (TCR) indicates how much the resistance changes with temperature. A low TCR is essential for applications where temperature fluctuations are common.

2. Latest Developments in Temperature Coefficient Specifications

Recent innovations have led to wirewound resistors with TCR values as low as 5 ppm/°C, enhancing their performance in precision applications.

IV. Performance Characteristics

1. Aging Effects

Wirewound resistors are known for their stability over time, but aging can still affect performance. Manufacturers are now using advanced materials and coatings to minimize aging effects.

2. Environmental Resistance

Modern wirewound resistors are designed to withstand harsh environmental conditions, including humidity, temperature extremes, and mechanical stress.

1. Impact of Frequency on Performance

The performance of wirewound resistors can be affected by frequency, particularly in high-frequency applications. Manufacturers are developing resistors with improved frequency response characteristics.

2. Applications Requiring High-Frequency Performance

Wirewound resistors are increasingly used in RF applications, where maintaining performance at high frequencies is critical.

1. Thermal Noise

Wirewound resistors generate thermal noise, which can impact sensitive applications. Recent designs aim to minimize this noise through improved construction techniques.

2. Flicker Noise

Flicker noise, or 1/f noise, is another consideration in precision applications. Manufacturers are working on designs that reduce flicker noise, enhancing overall performance.

V. Applications of Wirewound Resistors

1. Power Electronics

Wirewound resistors are widely used in power electronics for applications such as power supplies and inverters, where high power handling is essential.

2. Motor Control

In motor control systems, wirewound resistors are used for current sensing and feedback, ensuring efficient operation.

1. Audio Equipment

Wirewound resistors are commonly found in audio equipment, where they are used in volume controls and equalizers to provide precise adjustments.

2. Home Appliances

In home appliances, wirewound resistors are used for temperature control and circuit protection, ensuring safe and efficient operation.

1. Engine Control Units

Wirewound resistors are critical in engine control units, where they help regulate current and voltage for optimal engine performance.

2. Safety Systems

In automotive safety systems, wirewound resistors are used for sensor applications, ensuring reliable operation in critical situations.

VI. Recent Innovations and Trends

A. Miniaturization of Wirewound Resistors

The trend towards miniaturization has led to the development of smaller wirewound resistors that maintain performance while occupying less space, making them ideal for compact electronic devices.

B. Enhanced Thermal Management Techniques

Innovations in thermal management have improved the heat dissipation capabilities of wirewound resistors, allowing them to operate efficiently in high-power applications.

C. Integration with Smart Technologies

Wirewound resistors are increasingly being integrated with smart technologies, enabling features such as remote monitoring and control in various applications.

D. Sustainability and Eco-Friendly Materials

Manufacturers are focusing on sustainability by using eco-friendly materials and processes in the production of wirewound resistors, aligning with global efforts to reduce environmental impact.

VII. Conclusion

A. Summary of Key Points

Wirewound resistors are essential components in electronic circuits, offering precise resistance values and high power handling capabilities. Recent advancements in specifications, performance characteristics, and applications highlight their importance in various industries.

B. Future Outlook for Wirewound Resistor Technology

As technology continues to evolve, wirewound resistors will likely see further innovations in miniaturization, thermal management, and integration with smart technologies, enhancing their performance and applicability.

C. Importance of Staying Updated with Specifications for Engineers and Designers

For engineers and designers, staying updated with the latest specifications and advancements in wirewound resistors is crucial for ensuring optimal performance in their designs.

VIII. References

A. Academic Journals

- IEEE Transactions on Components, Packaging and Manufacturing Technology

- Journal of Electronic Materials

B. Industry Standards and Guidelines

- International Electrotechnical Commission (IEC) Standards

- American National Standards Institute (ANSI) Guidelines

C. Manufacturer Specifications and Datasheets

- Vishay Precision Group

- Ohmite Manufacturing Company

This comprehensive overview of the latest wirewound resistor specifications provides valuable insights for professionals in the electronics industry, ensuring they are well-informed about this critical component.