What are the comparative differences between mainstream high-power resistor models?

Comparative Differences Between Mainstream High-Power Resistor Models

I. Introduction

High-power resistors are essential components in various electronic applications, designed to handle significant amounts of power while maintaining stability and reliability. These resistors play a crucial role in power electronics, industrial machinery, automotive systems, and aerospace technologies. As the demand for efficient and robust electronic systems continues to grow, understanding the comparative differences between mainstream high-power resistor models becomes increasingly important. This article aims to provide a comprehensive comparison of popular high-power resistor models, focusing on their specifications, performance metrics, and application-specific considerations.

II. Overview of High-Power Resistors

A. Function and Applications

High-power resistors are designed to dissipate large amounts of electrical energy as heat. They are commonly used in:

1. **Power Electronics**: Inverters, converters, and other power management systems rely on high-power resistors to regulate voltage and current.

2. **Industrial Applications**: High-power resistors are used in braking systems, load banks, and testing equipment to manage energy dissipation.

3. **Automotive and Aerospace**: These resistors are critical in electric vehicles, hybrid systems, and aerospace applications, where reliability and performance are paramount.

B. Key Specifications

When evaluating high-power resistors, several key specifications must be considered:

1. **Power Rating**: This indicates the maximum power the resistor can handle without overheating.

2. **Resistance Value**: The resistance value determines how much current will flow through the resistor for a given voltage.

3. **Tolerance**: This specification indicates how much the actual resistance can vary from the stated value.

4. **Temperature Coefficient**: This measures how much the resistance changes with temperature, which is crucial for maintaining performance in varying environmental conditions.

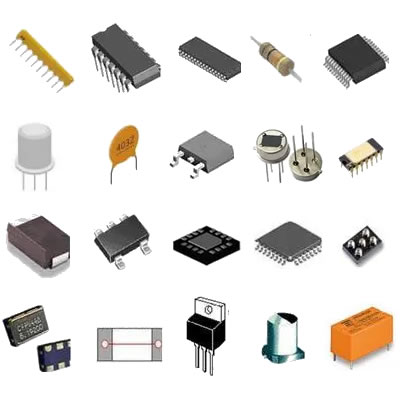

III. Types of High-Power Resistors

High-power resistors come in various types, each with unique construction, materials, advantages, and disadvantages.

A. Wirewound Resistors

1. **Construction and Materials**: Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core.

2. **Advantages and Disadvantages**: They offer high power ratings and excellent thermal stability but can be bulky and have lower frequency response.

B. Thick Film Resistors

1. **Construction and Materials**: Thick film resistors are made by applying a thick layer of resistive material onto a substrate.

2. **Advantages and Disadvantages**: They are compact and cost-effective but may have lower power ratings compared to wirewound resistors.

C. Thin Film Resistors

1. **Construction and Materials**: Thin film resistors are created by depositing a thin layer of resistive material onto a substrate.

2. **Advantages and Disadvantages**: They provide high precision and stability but are generally more expensive and have lower power ratings.

D. Ceramic Resistors

1. **Construction and Materials**: Ceramic resistors are made from a ceramic material that can withstand high temperatures.

2. **Advantages and Disadvantages**: They offer excellent thermal stability and power handling but can be more fragile than other types.

IV. Comparative Analysis of Mainstream High-Power Resistor Models

A. Popular Models and Manufacturers

Several manufacturers dominate the high-power resistor market, each offering a range of models with distinct features:

1. **Vishay**: Known for its wide selection of wirewound and thick film resistors, Vishay products are recognized for their reliability and performance.

2. **Ohmite**: Specializes in high-power resistors, particularly wirewound and ceramic types, with a focus on industrial applications.

3. **TE Connectivity**: Offers a variety of high-power resistors, including thick film and wirewound options, known for their durability.

4. **Bourns**: Provides a range of high-power resistors, emphasizing compact designs and high precision.

B. Performance Metrics

When comparing high-power resistor models, several performance metrics are critical:

1. **Power Handling Capabilities**: Wirewound resistors typically have the highest power ratings, making them suitable for demanding applications. Thick film resistors offer moderate power handling, while thin film resistors are best for low-power applications.

2. **Thermal Stability**: Wirewound and ceramic resistors excel in thermal stability, maintaining performance under varying temperatures. Thick film resistors may experience drift in resistance values at high temperatures.

3. **Frequency Response**: Thin film resistors generally provide the best frequency response, making them ideal for high-frequency applications, while wirewound resistors may have limitations due to their inductive nature.

C. Cost Considerations

Cost is a significant factor when selecting high-power resistors:

1. **Price Range of Different Models**: Wirewound resistors tend to be more expensive due to their construction and performance capabilities. Thick film resistors are generally more affordable, while thin film resistors are the most expensive due to their precision.

2. **Cost vs. Performance Analysis**: While higher-priced models may offer better performance and reliability, it is essential to evaluate the specific application requirements to determine the best value.

V. Application-Specific Considerations

A. Choosing the Right Resistor for Specific Applications

Selecting the appropriate high-power resistor depends on the application:

1. **Industrial vs. Automotive Applications**: Industrial applications may require robust wirewound or ceramic resistors, while automotive applications may benefit from compact thick film resistors.

2. **High-Frequency Applications**: For applications involving high frequencies, thin film resistors are preferred due to their superior frequency response.

B. Environmental Factors

Environmental conditions can significantly impact resistor performance:

1. **Operating Temperature Range**: Resistors must be chosen based on their ability to operate within the required temperature range for the application.

2. **Humidity and Moisture Resistance**: In environments with high humidity, selecting resistors with moisture-resistant coatings or materials is crucial to prevent failure.

VI. Future Trends in High-Power Resistor Technology

A. Innovations in Materials and Design

The future of high-power resistors is likely to see advancements in materials and design, leading to improved performance and efficiency. New materials may enhance thermal conductivity and reduce size while maintaining power handling capabilities.

B. Impact of Emerging Technologies on Resistor Performance

As technologies such as electric vehicles and renewable energy systems evolve, the demand for high-power resistors will increase. This will drive innovation in resistor design to meet the specific needs of these applications.

C. Sustainability and Eco-Friendly Options

With growing environmental concerns, manufacturers are exploring sustainable materials and production methods for high-power resistors. This trend will likely lead to the development of eco-friendly options that do not compromise performance.

VII. Conclusion

In summary, high-power resistors are vital components in various electronic applications, and understanding the comparative differences between mainstream models is essential for selecting the right resistor for specific needs. Key specifications, performance metrics, and application-specific considerations play a crucial role in this decision-making process. As technology continues to advance, the future of high-power resistors looks promising, with innovations in materials and design paving the way for enhanced performance and sustainability.

VIII. References

1. Vishay Intertechnology. (2023). High-Power Resistors. Retrieved from [Vishay website]

2. Ohmite Manufacturing Company. (2023). Wirewound Resistors. Retrieved from [Ohmite website]

3. TE Connectivity. (2023). Resistor Solutions. Retrieved from [TE Connectivity website]

4. Bourns, Inc. (2023). High-Power Resistors. Retrieved from [Bourns website]

5. Electronic Components Industry Reports. (2023). Trends in Resistor Technology. Retrieved from [Industry Reports website]

This blog post provides a detailed overview of the comparative differences between mainstream high-power resistor models, offering insights into their specifications, performance, and applications. By understanding these factors, engineers and designers can make informed decisions when selecting high-power resistors for their projects.