The latest aluminum shell resistor specifications

The Latest Aluminum Shell Resistor Specifications

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, aluminum shell resistors have gained significant attention due to their unique properties and advantages. This article aims to provide an in-depth look at aluminum shell resistors, exploring their specifications, performance characteristics, applications, and future trends in technology.

II. Understanding Aluminum Shell Resistors

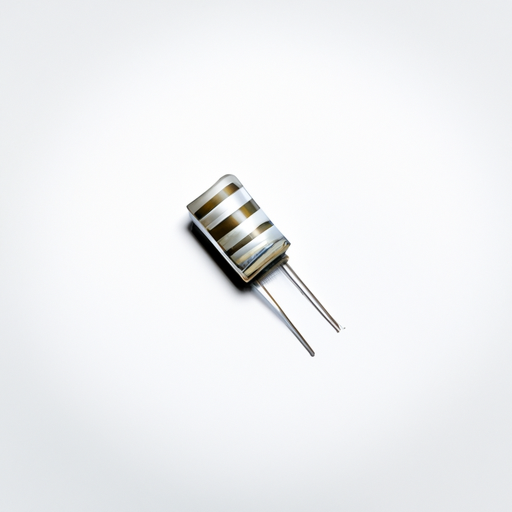

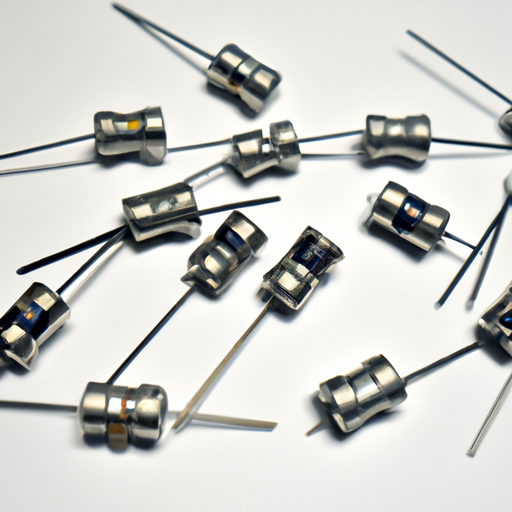

A. Composition and Construction

Aluminum shell resistors are designed with a robust aluminum casing that provides both structural integrity and thermal management. The primary materials used in their construction include aluminum for the shell, resistive elements made from metal film or wire-wound materials, and insulating materials that ensure electrical safety.

1. Materials Used

The resistive element is typically made from a metal alloy, which offers a stable resistance value and good thermal conductivity. The aluminum shell not only protects the internal components but also aids in heat dissipation, making these resistors suitable for high-power applications.

2. Design Features

The design of aluminum shell resistors often includes features such as mounting brackets, heat sinks, and terminals for easy integration into electronic circuits. These design elements enhance their usability in various applications, from industrial machinery to consumer electronics.

B. Advantages of Aluminum Shell Resistors

Aluminum shell resistors offer several advantages that make them a preferred choice in many applications.

1. Thermal Management

One of the standout features of aluminum shell resistors is their excellent thermal management capabilities. The aluminum casing allows for efficient heat dissipation, which is critical in preventing overheating and ensuring reliable performance in high-power applications.

2. Durability and Reliability

The robust construction of aluminum shell resistors contributes to their durability and reliability. They can withstand harsh environmental conditions, making them suitable for industrial and outdoor applications.

3. Lightweight Properties

Compared to other resistor types, aluminum shell resistors are relatively lightweight. This characteristic is particularly beneficial in applications where weight is a critical factor, such as in aerospace and automotive industries.

III. Key Specifications of Aluminum Shell Resistors

Understanding the specifications of aluminum shell resistors is essential for selecting the right component for a specific application.

A. Resistance Values

Aluminum shell resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. The tolerance levels, which indicate how much the actual resistance can vary from the specified value, are also crucial. Common tolerance levels range from ±1% to ±5%, depending on the application requirements.

B. Power Ratings

Power ratings are a critical specification for resistors, indicating the maximum power the resistor can handle without failure. Common power ratings for aluminum shell resistors include 1W, 5W, 10W, and higher. The power rating directly impacts the resistor's performance, with higher ratings allowing for greater heat dissipation and improved reliability.

C. Temperature Coefficients

The temperature coefficient of resistance (TCR) measures how much the resistance value changes with temperature. For aluminum shell resistors, typical TCR values range from ±50 to ±100 ppm/°C. A lower TCR indicates better stability over temperature variations, which is essential for precision applications.

D. Voltage Ratings

Voltage ratings specify the maximum voltage that can be applied across the resistor without risking breakdown. Aluminum shell resistors typically have high voltage ratings, making them suitable for various applications, including power electronics and automotive systems.

IV. Performance Characteristics

A. Thermal Performance

The thermal performance of aluminum shell resistors is one of their most significant advantages. They can effectively dissipate heat generated during operation, which is crucial for maintaining performance and longevity. The impact of ambient temperature on performance is also a consideration, as higher temperatures can affect resistance values and overall reliability.

B. Frequency Response

Aluminum shell resistors exhibit stable performance across a range of frequencies, making them suitable for high-frequency applications. Their behavior at different frequencies is essential for applications in RF circuits and signal processing, where maintaining signal integrity is critical.

C. Load Life and Reliability

Load life testing is a standard method for assessing the longevity of resistors. Aluminum shell resistors are subjected to various stress conditions to determine their lifespan. Factors such as temperature, humidity, and electrical load can significantly affect their reliability, making it essential to choose resistors that meet the specific demands of the application.

V. Applications of Aluminum Shell Resistors

Aluminum shell resistors find applications across various industries due to their unique properties.

A. Industrial Applications

In industrial settings, aluminum shell resistors are commonly used in power electronics, where they help manage current flow and protect sensitive components. They also play a vital role in automation systems, ensuring reliable operation of machinery and equipment.

B. Consumer Electronics

In the realm of consumer electronics, aluminum shell resistors are found in audio equipment, where they help maintain sound quality by managing signal levels. They are also used in home appliances, contributing to energy efficiency and performance.

C. Automotive and Aerospace

The automotive and aerospace industries rely heavily on aluminum shell resistors for their lightweight properties and durability. In vehicles, they are used in electronic control units, sensors, and power distribution systems. In avionics, their reliability is critical for ensuring the safety and performance of aircraft systems.

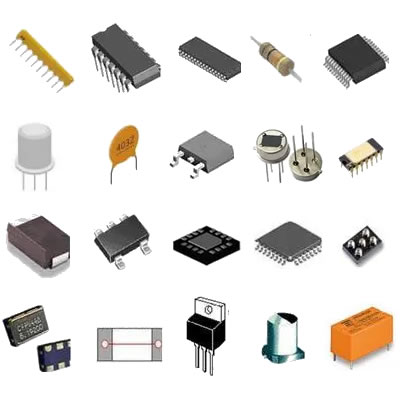

VI. Comparison with Other Resistor Types

When considering resistors for specific applications, it's essential to compare aluminum shell resistors with other types.

A. Aluminum Shell vs. Ceramic Resistors

Ceramic resistors are known for their high-temperature stability and resistance to environmental factors. However, aluminum shell resistors offer better thermal management and are generally lighter, making them more suitable for applications where weight is a concern.

B. Aluminum Shell vs. Wire-Wound Resistors

Wire-wound resistors provide high precision and stability but can be bulkier and heavier than aluminum shell resistors. The choice between the two often depends on the specific requirements of the application, such as size, weight, and power handling capabilities.

C. Advantages and Disadvantages of Each Type

Each resistor type has its advantages and disadvantages. Aluminum shell resistors excel in thermal management and lightweight properties, while ceramic and wire-wound resistors may offer better precision or stability in specific conditions. The choice ultimately depends on the application requirements.

VII. Future Trends in Aluminum Shell Resistor Technology

As technology continues to evolve, so do the specifications and applications of aluminum shell resistors.

A. Innovations in Materials and Design

Ongoing research and development are leading to innovations in materials and design, enhancing the performance and capabilities of aluminum shell resistors. New materials may improve thermal conductivity and resistance stability, while advanced designs can further optimize heat dissipation.

B. Increasing Demand for High-Performance Resistors

With the growing demand for high-performance electronic devices, the need for reliable and efficient resistors is on the rise. Aluminum shell resistors are well-positioned to meet this demand, particularly in applications requiring high power and thermal management.

C. Environmental Considerations and Sustainability

As industries move towards more sustainable practices, the development of environmentally friendly resistor technologies is becoming increasingly important. Manufacturers are exploring ways to reduce waste and improve the recyclability of resistor components, aligning with global sustainability goals.

VIII. Conclusion

Aluminum shell resistors are a vital component in modern electronics, offering a unique combination of thermal management, durability, and lightweight properties. Understanding their specifications, performance characteristics, and applications is essential for selecting the right resistor for specific needs. As technology advances, aluminum shell resistors will continue to play a crucial role in various industries, adapting to meet the demands of high-performance electronics.

IX. References

For further reading on aluminum shell resistors and related topics, consider exploring the following sources:

1. Electronic Component Standards and Guidelines

2. Industry publications on resistor technology

3. Manufacturer datasheets for specific aluminum shell resistor models

By staying informed about the latest developments in resistor technology, engineers and designers can make better choices for their electronic circuits, ensuring optimal performance and reliability.