What are the product standards for frequency sensitive resistors?

What are the Product Standards for Frequency Sensitive Resistors?

I. Introduction

In the realm of electronics, resistors play a pivotal role in controlling current flow and voltage levels within circuits. Among these, frequency sensitive resistors are specialized components designed to perform optimally across varying frequencies. As technology advances and applications become more complex, the need for stringent product standards for these resistors has never been more critical. This article delves into the definition of frequency sensitive resistors, their importance, the relevant product standards, testing methods, challenges in standardization, and future trends in the industry.

II. Understanding Frequency Sensitive Resistors

A. Explanation of Frequency Sensitivity in Resistors

Frequency sensitivity refers to how a resistor's performance can change with different frequencies of electrical signals. In electronic circuits, resistors are not merely passive components; they interact with other elements, and their behavior can be influenced by the frequency of the signals passing through them.

1. **Role of Resistors in Electronic Circuits**: Resistors are fundamental components that limit current, divide voltages, and dissipate energy as heat. Their performance is crucial in ensuring that circuits function as intended.

2. **Impact of Frequency on Resistor Performance**: At higher frequencies, parasitic capacitance and inductance can affect a resistor's behavior, leading to variations in resistance, noise levels, and overall performance. This frequency-dependent behavior necessitates the development of specialized resistors that can maintain performance across a range of frequencies.

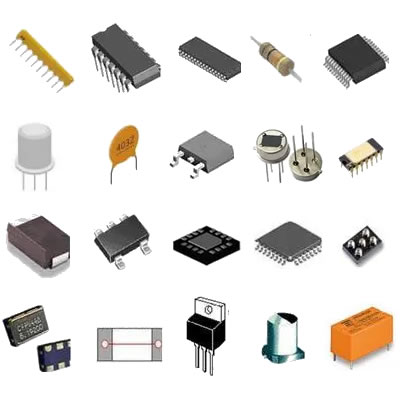

B. Types of Frequency Sensitive Resistors

Frequency sensitive resistors come in various types, each with unique characteristics suited for specific applications:

1. **Thin Film Resistors**: Known for their precision and stability, thin film resistors are often used in high-frequency applications due to their low parasitic effects.

2. **Thick Film Resistors**: These resistors are more robust and can handle higher power levels, making them suitable for applications where durability is essential.

3. **Wire-Wound Resistors**: Wire-wound resistors are excellent for high-frequency applications, offering low inductance and high power ratings.

C. Applications of Frequency Sensitive Resistors

Frequency sensitive resistors find applications in various fields, including:

1. **RF (Radio Frequency) Applications**: In RF circuits, resistors must maintain performance across a wide frequency range to ensure signal integrity.

2. **Audio Equipment**: High-fidelity audio systems require resistors that can handle audio frequencies without introducing distortion.

3. **Telecommunications**: In telecommunications, frequency sensitive resistors are crucial for maintaining signal quality and reducing noise in transmission lines.

III. Importance of Product Standards

Product standards are essential in the electronics industry for several reasons:

A. Ensuring Reliability and Performance

Standards help ensure that frequency sensitive resistors perform reliably under specified conditions. This reliability is crucial for applications where failure can lead to significant consequences, such as in medical devices or aerospace systems.

B. Facilitating Compatibility and Interoperability

With numerous manufacturers producing frequency sensitive resistors, standards facilitate compatibility between components from different sources. This interoperability is vital for system integration and reduces the risk of failures due to mismatched components.

C. Enhancing Safety and Reducing Risks

Adhering to established standards helps mitigate risks associated with electrical components, such as overheating or failure. This is particularly important in high-power applications where safety is paramount.

D. Supporting Innovation and Market Growth

Standards provide a framework for innovation, allowing manufacturers to develop new technologies while ensuring that products meet minimum performance criteria. This balance fosters market growth and encourages competition.

IV. Key Product Standards for Frequency Sensitive Resistors

Several organizations set product standards for frequency sensitive resistors, ensuring quality and performance across the industry.

A. International Electrotechnical Commission (IEC) Standards

The IEC is a global organization that develops and publishes international standards for electrical and electronic devices.

1. **Overview of IEC Standards Relevant to Resistors**: IEC standards cover various aspects of resistor performance, including temperature coefficients, power ratings, and frequency response.

2. **Specific IEC Standards for Frequency Sensitive Resistors**: IEC 60115-1 outlines general specifications for fixed resistors, while IEC 60115-2 provides specific requirements for different types of resistors, including those sensitive to frequency.

B. Institute of Electrical and Electronics Engineers (IEEE) Standards

The IEEE plays a crucial role in establishing standards for electronic components, including resistors.

1. **Role of IEEE in Setting Standards for Electronic Components**: The IEEE develops standards that address performance, testing, and reliability, ensuring that components meet industry needs.

2. **Relevant IEEE Standards for Resistors**: IEEE 1620 provides guidelines for the testing of resistors in high-frequency applications, ensuring that they meet performance criteria.

C. American National Standards Institute (ANSI) Standards

ANSI oversees the development of standards in the United States, including those for electronic components.

1. **Overview of ANSI's Role in Standardization**: ANSI coordinates the development of voluntary consensus standards, promoting quality and safety in products.

2. **Specific ANSI Standards Applicable to Frequency Sensitive Resistors**: ANSI/IEEE C57.12.00 outlines standards for resistors used in power applications, ensuring they can handle the demands of high-frequency environments.

D. Other Relevant Standards and Organizations

1. **Military Standards (MIL-PRF)**: Military specifications often set stringent requirements for components used in defense applications, including frequency sensitive resistors.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: CENELEC develops standards for electrical and electronic components in Europe, ensuring compliance with EU regulations.

V. Testing and Compliance

A. Testing Methods for Frequency Sensitive Resistors

To ensure compliance with standards, various testing methods are employed:

1. **Impedance Measurement**: This method assesses how a resistor behaves at different frequencies, providing insights into its performance characteristics.

2. **Temperature Coefficient Testing**: This testing evaluates how a resistor's resistance changes with temperature, which is crucial for maintaining performance in varying environmental conditions.

3. **Frequency Response Analysis**: This analysis examines how a resistor responds to different frequencies, helping to identify any performance issues.

B. Certification Processes for Compliance with Standards

1. **Role of Third-Party Testing Laboratories**: Independent laboratories conduct tests to verify that resistors meet established standards, providing an unbiased assessment of performance.

2. **Importance of Documentation and Traceability**: Maintaining thorough documentation of testing processes and results is essential for compliance and quality assurance.

VI. Challenges in Standardization

Despite the importance of standards, several challenges persist in the standardization of frequency sensitive resistors:

A. Variability in Manufacturing Processes

Different manufacturing techniques can lead to variations in resistor performance, making it challenging to establish uniform standards.

B. Rapid Technological Advancements

As technology evolves, new materials and designs emerge, necessitating continuous updates to existing standards to keep pace with innovation.

C. Global Market Considerations

With a global market for electronic components, harmonizing standards across different regions can be complex, as regulations and requirements may vary.

D. Balancing Innovation with Standard Compliance

Manufacturers must navigate the fine line between innovating new products and ensuring compliance with established standards, which can sometimes stifle creativity.

VII. Future Trends in Frequency Sensitive Resistors

A. Emerging Technologies and Their Impact on Standards

As new technologies, such as 5G and IoT, emerge, the demand for high-performance frequency sensitive resistors will increase, prompting the need for updated standards.

B. The Role of Automation and AI in Testing and Compliance

Automation and artificial intelligence are poised to revolutionize testing and compliance processes, making them more efficient and accurate.

C. Anticipated Changes in Industry Standards

As the industry evolves, we can expect to see more dynamic and flexible standards that accommodate rapid technological advancements while ensuring safety and performance.

VIII. Conclusion

In conclusion, product standards for frequency sensitive resistors are vital for ensuring reliability, compatibility, and safety in electronic applications. As technology continues to advance, the importance of these standards will only grow, necessitating ongoing efforts to adapt and refine them. The future of frequency sensitive resistors will undoubtedly be shaped by emerging technologies, innovative testing methods, and a commitment to maintaining high standards in performance and safety. As we move forward, the collaboration between manufacturers, standard-setting organizations, and regulatory bodies will be crucial in fostering a robust and innovative electronics industry.