What are the advantages of metal film resistor products?

What are the Advantages of Metal Film Resistor Products?

I. Introduction

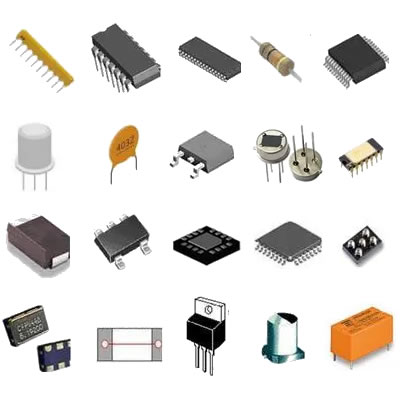

Resistors are fundamental components in electronic circuits, serving to limit current flow, divide voltages, and provide biasing for active devices. Among the various types of resistors available, metal film resistors stand out due to their unique construction and performance characteristics. This article aims to explore the advantages of metal film resistors, highlighting their precision, stability, and suitability for a wide range of applications.

II. Construction and Composition of Metal Film Resistors

A. Description of Materials Used

Metal film resistors are constructed using a thin layer of metal deposited onto a ceramic substrate. The metal film layer is typically made from materials such as nickel-chromium or tantalum, which are known for their excellent electrical properties. The substrate, often made of high-quality ceramic, provides mechanical stability and thermal conductivity.

B. Manufacturing Process

The manufacturing of metal film resistors employs thin-film technology, which allows for precise control over the thickness and uniformity of the metal layer. This precision is crucial in achieving the desired resistance values and tolerances. The process involves sputtering or evaporation techniques to deposit the metal film onto the substrate, followed by laser trimming to fine-tune the resistance value. This meticulous production process results in resistors that exhibit high accuracy and reliability.

III. Key Advantages of Metal Film Resistors

A. High Precision and Tolerance

One of the standout features of metal film resistors is their high precision and low tolerance levels, often as low as ±0.1% or ±0.5%. This level of accuracy is essential in applications where precise resistance values are critical. In comparison, carbon film resistors typically have tolerances of ±5% to ±10%, making metal film resistors a superior choice for precision applications.

B. Low Temperature Coefficient

The temperature coefficient of resistance (TCR) indicates how much a resistor's value changes with temperature. Metal film resistors have a low TCR, often in the range of ±5 to ±25 ppm/°C. This characteristic ensures that their performance remains stable across a wide temperature range, making them ideal for environments where temperature fluctuations are common. In contrast, other resistor types, such as carbon film, can exhibit higher TCR values, leading to greater variability in performance.

C. Excellent Stability and Reliability

Metal film resistors are known for their excellent stability and reliability over time. They are resistant to environmental factors such as humidity, temperature changes, and mechanical stress. This durability ensures long-term performance consistency, making them suitable for critical applications where failure is not an option. In contrast, carbon film resistors may degrade more quickly under harsh conditions, leading to potential circuit failures.

D. Low Noise Characteristics

Noise in electronic circuits can significantly impact performance, especially in sensitive applications such as audio and measurement devices. Metal film resistors exhibit low noise characteristics, which means they generate minimal electrical noise during operation. This feature is particularly beneficial in audio equipment, where low noise levels are essential for high-fidelity sound reproduction. In comparison, wire-wound resistors can produce higher noise levels, making them less suitable for such applications.

E. Wide Range of Resistance Values

Metal film resistors are available in a wide range of resistance values, from a few ohms to several megaohms. This versatility allows designers to select the appropriate resistor for their specific application, whether it be in precision measurement devices or consumer electronics. The availability of various resistance values provides flexibility in circuit design, enabling engineers to optimize performance based on their requirements.

IV. Applications of Metal Film Resistors

A. Use in Precision Equipment

Metal film resistors are commonly used in precision equipment, such as medical devices and measurement instruments. In medical applications, where accuracy is paramount, these resistors ensure that readings are reliable and consistent. Similarly, in measurement instruments, metal film resistors contribute to the overall precision of the device, allowing for accurate data collection and analysis.

B. Role in Audio Equipment

In audio applications, the low noise characteristics of metal film resistors make them a preferred choice for high-quality audio equipment. They help maintain signal integrity, ensuring that sound reproduction is clear and free from unwanted noise. This is particularly important in high-fidelity audio systems, where even the slightest noise can detract from the listening experience.

C. Applications in Telecommunications

Telecommunications devices require components that can operate reliably under varying conditions. Metal film resistors are well-suited for this purpose, as they offer stability and performance consistency. Their ability to withstand environmental factors makes them ideal for use in communication devices, where reliability is critical for maintaining connectivity.

D. Use in Consumer Electronics

In everyday consumer electronics, metal film resistors play a vital role in ensuring device performance. From televisions to smartphones, these resistors contribute to the overall functionality and reliability of the devices we use daily. Their precision and stability make them a popular choice among manufacturers looking to deliver high-quality products.

V. Comparison with Other Resistor Types

A. Metal Film vs. Carbon Film Resistors

When comparing metal film resistors to carbon film resistors, the differences in performance become evident. Metal film resistors offer superior precision, lower noise, and better stability, making them ideal for high-performance applications. While carbon film resistors may be more cost-effective, they do not provide the same level of accuracy and reliability, which can be critical in certain applications.

B. Metal Film vs. Wire-Wound Resistors

Wire-wound resistors are known for their high power ratings and are often used in applications requiring high wattage. However, they tend to be larger and heavier than metal film resistors, making them less suitable for compact designs. Additionally, wire-wound resistors can introduce higher noise levels, which may not be acceptable in sensitive applications. In contrast, metal film resistors offer a more compact solution with lower noise, making them preferable for many modern electronic designs.

VI. Conclusion

In summary, metal film resistors offer a range of advantages that make them a preferred choice in various electronic applications. Their high precision, low temperature coefficient, excellent stability, low noise characteristics, and wide range of resistance values position them as a superior option compared to other resistor types. As technology continues to evolve, the demand for high-performance components like metal film resistors will likely increase, driving further advancements in resistor technology. Selecting the right resistor for specific applications is crucial, and understanding the benefits of metal film resistors can help engineers and designers make informed decisions.

VII. References

For further exploration of metal film resistors and their applications, consider the following resources:

1. "Resistor Technology: A Comprehensive Guide" - A detailed overview of various resistor types and their applications.

2. "Precision Resistors: The Key to Accurate Measurements" - An article discussing the importance of precision resistors in measurement devices.

3. "Understanding Noise in Electronic Circuits" - A resource that delves into the impact of noise on circuit performance and how to mitigate it.

By understanding the advantages of metal film resistors, engineers and designers can enhance the performance and reliability of their electronic circuits, ensuring that they meet the demands of modern technology.