What is the comparison difference between mainstream film capacitor models?

What is the Comparison Difference Between Mainstream Film Capacitor Models?

I. Introduction

A. Definition of Film Capacitors

Film capacitors are passive electronic components that store electrical energy in an electric field. They are constructed using thin plastic films as the dielectric material, which separates the conductive plates. This design allows film capacitors to exhibit excellent electrical characteristics, making them a popular choice in various electronic applications.

B. Importance of Film Capacitors in Electronic Circuits

Film capacitors play a crucial role in electronic circuits, serving functions such as filtering, coupling, decoupling, and energy storage. Their stability, reliability, and low loss characteristics make them ideal for high-frequency applications, audio equipment, and power electronics. As technology advances, the demand for high-performance capacitors continues to grow, highlighting the importance of understanding the differences between various film capacitor models.

C. Purpose of the Comparison

This blog post aims to compare mainstream film capacitor models, providing insights into their characteristics, applications, and performance metrics. By understanding these differences, engineers and designers can make informed decisions when selecting the right capacitor for their specific needs.

II. Overview of Film Capacitor Technology

A. Basic Principles of Film Capacitors

1. Construction and Materials

Film capacitors are typically constructed from thin layers of dielectric materials, such as polyester, polypropylene, or polycarbonate, sandwiched between conductive plates. The choice of dielectric material significantly influences the capacitor's performance characteristics, including capacitance, voltage rating, and temperature stability.

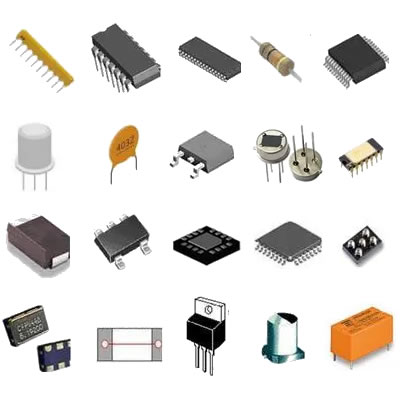

2. Types of Film Capacitors

There are several types of film capacitors, each with unique properties and applications. The most common types include polyester, polypropylene, polycarbonate, and polystyrene capacitors. Each type has its advantages and disadvantages, making them suitable for different applications.

B. Advantages of Film Capacitors

1. Stability and Reliability

Film capacitors are known for their excellent stability over time and temperature. They exhibit minimal capacitance drift, making them suitable for precision applications.

2. Low Loss Characteristics

Film capacitors have low equivalent series resistance (ESR), which results in minimal energy loss during operation. This characteristic is particularly important in high-frequency applications where efficiency is critical.

3. High Voltage Ratings

Many film capacitors can handle high voltage levels, making them suitable for power electronics and other demanding applications.

III. Common Types of Film Capacitors

A. Polyester Film Capacitors

1. Characteristics

Polyester film capacitors are known for their affordability and versatility. They typically have a capacitance range of a few nanofarads to several microfarads and can handle voltage ratings up to 630V.

2. Applications

These capacitors are commonly used in general-purpose applications, including power supplies, audio equipment, and consumer electronics.

B. Polypropylene Film Capacitors

1. Characteristics

Polypropylene film capacitors offer superior performance compared to polyester capacitors. They have lower ESR, higher voltage ratings (up to 1000V), and better temperature stability.

2. Applications

These capacitors are often used in audio applications, power electronics, and high-frequency circuits due to their low loss characteristics.

C. Polycarbonate Film Capacitors

1. Characteristics

Polycarbonate film capacitors are known for their excellent stability and reliability. They can handle high voltage ratings and have a wide capacitance range.

2. Applications

These capacitors are suitable for precision applications, including timing circuits and high-frequency filters.

D. Other Types (e.g., Polystyrene, PTFE)

1. Characteristics

Polystyrene capacitors are known for their low dielectric absorption and high stability, while PTFE (Teflon) capacitors offer excellent thermal stability and low loss characteristics.

2. Applications

Polystyrene capacitors are often used in audio and RF applications, while PTFE capacitors are suitable for high-temperature environments and demanding applications.

IV. Key Parameters for Comparison

When comparing film capacitor models, several key parameters should be considered:

A. Capacitance Range

The capacitance range indicates the amount of charge a capacitor can store. Different applications may require different capacitance values.

B. Voltage Ratings

Voltage ratings indicate the maximum voltage a capacitor can handle without failure. Selecting a capacitor with an appropriate voltage rating is crucial for ensuring reliability.

C. Temperature Coefficients

Temperature coefficients indicate how capacitance changes with temperature. Capacitors with low temperature coefficients are preferred for precision applications.

D. Tolerance Levels

Tolerance levels indicate the allowable deviation from the nominal capacitance value. Tight tolerance levels are essential for applications requiring high precision.

E. Equivalent Series Resistance (ESR)

ESR is a measure of the internal resistance of a capacitor. Lower ESR values are preferred for high-frequency applications to minimize energy loss.

F. Lifetime and Reliability

The expected lifetime and reliability of a capacitor are critical factors, especially in applications where failure can lead to significant consequences.

G. Cost Considerations

Cost is always a factor in component selection. While high-performance capacitors may offer superior characteristics, they often come at a higher price.

V. Comparison of Popular Film Capacitor Models

A. Model A: Overview and Specifications

1. Key Features

Model A is a polypropylene film capacitor with a capacitance range of 1nF to 10µF and a voltage rating of 630V. It features low ESR and excellent temperature stability.

2. Pros and Cons

**Pros:** Low loss, high reliability, suitable for audio applications.

**Cons:** Higher cost compared to polyester capacitors.

B. Model B: Overview and Specifications

1. Key Features

Model B is a polyester film capacitor with a capacitance range of 10nF to 100µF and a voltage rating of 400V. It is known for its affordability and versatility.

2. Pros and Cons

**Pros:** Cost-effective, widely available.

**Cons:** Higher ESR, less stable than polypropylene capacitors.

C. Model C: Overview and Specifications

1. Key Features

Model C is a polycarbonate film capacitor with a capacitance range of 1nF to 10µF and a voltage rating of 1000V. It offers excellent stability and reliability.

2. Pros and Cons

**Pros:** High voltage rating, low temperature coefficient.

**Cons:** Higher cost, limited availability.

D. Model D: Overview and Specifications

1. Key Features

Model D is a polystyrene film capacitor with a capacitance range of 10pF to 1µF and a voltage rating of 250V. It is known for its low dielectric absorption.

2. Pros and Cons

**Pros:** Excellent stability, low loss characteristics.

**Cons:** Limited capacitance range, higher cost.

VI. Application-Specific Considerations

A. Audio Applications

1. Preferred Capacitor Types

In audio applications, polypropylene and polystyrene capacitors are often preferred due to their low loss characteristics and high stability.

2. Performance Metrics

Key performance metrics include low ESR, tight tolerance levels, and high voltage ratings to ensure optimal audio performance.

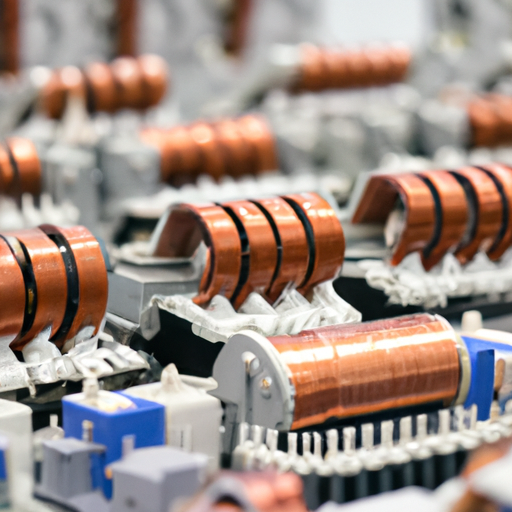

B. Power Electronics

1. Preferred Capacitor Types

Polypropylene and polyester capacitors are commonly used in power electronics due to their high voltage ratings and reliability.

2. Performance Metrics

Performance metrics include high voltage ratings, low ESR, and long lifetime to ensure reliable operation in demanding environments.

C. RF and High-Frequency Applications

1. Preferred Capacitor Types

In RF applications, polystyrene and polypropylene capacitors are often preferred for their low loss characteristics and stability.

2. Performance Metrics

Key performance metrics include low ESR, tight tolerance levels, and high-frequency response to ensure optimal performance.

VII. Future Trends in Film Capacitor Technology

A. Innovations in Materials

Advancements in dielectric materials are leading to the development of new film capacitors with improved performance characteristics, such as higher voltage ratings and lower loss.

B. Miniaturization and Integration

As electronic devices become smaller and more integrated, the demand for miniaturized film capacitors is increasing. Manufacturers are focusing on developing compact designs without compromising performance.

C. Environmental Considerations

With growing concerns about environmental sustainability, manufacturers are exploring eco-friendly materials and production processes for film capacitors.

VIII. Conclusion

A. Summary of Key Findings

In summary, film capacitors are essential components in electronic circuits, offering a range of characteristics and applications. Understanding the differences between various models, such as polyester, polypropylene, and polycarbonate capacitors, is crucial for selecting the right component for specific applications.

B. Recommendations for Selection

When selecting a film capacitor, consider key parameters such as capacitance range, voltage ratings, temperature coefficients, and cost. Additionally, evaluate the specific requirements of your application to ensure optimal performance.

C. Final Thoughts on the Importance of Choosing the Right Film Capacitor Model

Choosing the right film capacitor model is vital for ensuring the reliability and performance of electronic circuits. By understanding the differences between mainstream film capacitor models, engineers and designers can make informed decisions that enhance the overall functionality of their designs.

IX. References

A. Academic Journals

1. "Film Capacitors: A Review of Their Characteristics and Applications," Journal of Electronic Materials.

2. "Advancements in Film Capacitor Technology," IEEE Transactions on Industrial Electronics.

B. Industry Reports

1. "Global Film Capacitor Market Analysis," Market Research Future.

2. "Trends in Capacitor Technology," Electronics Weekly.

C. Manufacturer Specifications and Datasheets

1. Manufacturer A: Polyester Film Capacitor Datasheet.

2. Manufacturer B: Polypropylene Film Capacitor Specifications.

This comprehensive exploration of film capacitors provides a solid foundation for understanding their importance and the differences between various models, aiding in the selection process for specific applications.