How should spot aluminum electrolytic capacitors be selected?

How Should Spot Aluminum Electrolytic Capacitors Be Selected?

I. Introduction

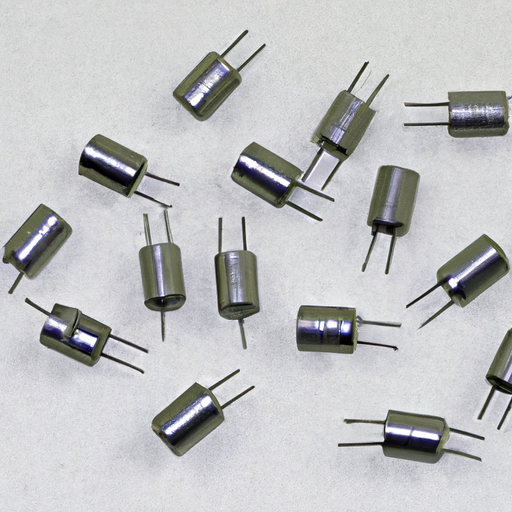

Aluminum electrolytic capacitors are essential components in a wide range of electronic devices, playing a crucial role in energy storage, filtering, and signal processing. These capacitors are known for their high capacitance values and relatively low cost, making them a popular choice in various applications. However, the selection of the right aluminum electrolytic capacitor is vital to ensure optimal performance and reliability in electronic circuits. This article will guide you through the key factors to consider when selecting aluminum electrolytic capacitors, helping you make informed decisions for your projects.

II. Understanding Aluminum Electrolytic Capacitors

A. Basic Structure and Function

Aluminum electrolytic capacitors consist of two conductive plates (anode and cathode) separated by an electrolyte. The anode is typically made of aluminum foil, which is oxidized to form a thin insulating layer of aluminum oxide. This oxide layer acts as the dielectric, allowing the capacitor to store electrical energy. The cathode is usually a liquid or solid electrolyte that facilitates the flow of current.

B. Key Characteristics

1. **Capacitance**: This is the primary characteristic of a capacitor, measured in farads (F). Aluminum electrolytic capacitors typically offer high capacitance values, ranging from microfarads (µF) to several thousand microfarads.

2. **Voltage Rating**: Each capacitor has a maximum voltage it can handle, known as the voltage rating. Exceeding this rating can lead to capacitor failure.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the internal resistance of the capacitor, affecting its efficiency and performance, especially in high-frequency applications.

4. **Temperature Coefficient**: This indicates how the capacitance value changes with temperature. It is essential to consider the operating temperature range of the application.

C. Applications of Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are widely used in various applications, including:

1. **Power Supply Filtering**: They smooth out voltage fluctuations in power supplies, ensuring stable operation of electronic devices.

2. **Signal Coupling and Decoupling**: These capacitors are used to couple and decouple signals in audio and radio frequency applications.

3. **Timing Circuits**: They play a crucial role in timing circuits, where precise timing is essential.

III. Factors to Consider When Selecting Aluminum Electrolytic Capacitors

A. Capacitance Value

1. **Determining Required Capacitance**: The first step in selecting a capacitor is to determine the required capacitance for your application. This can be based on the circuit design and the specific function the capacitor will serve.

2. **Tolerance Levels**: Capacitors come with different tolerance levels, indicating how much the actual capacitance can vary from the stated value. Common tolerances include ±10%, ±20%, and tighter tolerances for precision applications.

B. Voltage Rating

1. **Understanding Voltage Ratings**: The voltage rating of a capacitor indicates the maximum voltage it can withstand without failure. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage expected in the circuit.

2. **Safety Margins**: A good practice is to include a safety margin, typically 20-30% above the maximum operating voltage, to account for voltage spikes and variations.

C. ESR and Ripple Current

1. **Importance of ESR**: The equivalent series resistance (ESR) affects the capacitor's performance, especially in high-frequency applications. Lower ESR values are generally preferred for better efficiency and reduced heat generation.

2. **Ripple Current Ratings**: Ripple current is the AC component of the current flowing through the capacitor. Selecting a capacitor with an appropriate ripple current rating is essential to prevent overheating and ensure reliability.

D. Temperature and Lifetime Considerations

1. **Operating Temperature Range**: Aluminum electrolytic capacitors have specified operating temperature ranges. It is essential to select a capacitor that can operate effectively within the temperature conditions of your application.

2. **Expected Lifetime and Derating**: The lifetime of a capacitor is influenced by temperature and voltage. Derating the capacitor (operating it below its maximum ratings) can significantly extend its lifespan.

E. Physical Size and Form Factor

1. **PCB Space Constraints**: The physical size of the capacitor is an important consideration, especially in compact designs. Ensure that the selected capacitor fits within the available PCB space.

2. **Lead Configuration**: Different capacitors come with various lead configurations (e.g., radial or axial). Choose a configuration that suits your PCB layout and assembly process.

IV. Environmental Considerations

A. Humidity and Moisture Resistance

Aluminum electrolytic capacitors can be sensitive to humidity and moisture, which can lead to corrosion and failure. Selecting capacitors with appropriate moisture resistance ratings is crucial for applications in humid environments.

B. RoHS Compliance and Environmental Regulations

Ensure that the selected capacitors comply with RoHS (Restriction of Hazardous Substances) regulations and other environmental standards. This is particularly important for products intended for markets with strict environmental regulations.

C. Impact of Operating Environment on Selection

Consider the operating environment of the application, including factors such as temperature, humidity, and exposure to chemicals. These factors can influence the selection of suitable capacitors.

V. Reliability and Quality Factors

A. Manufacturer Reputation

Choosing capacitors from reputable manufacturers can significantly impact the reliability of your design. Established manufacturers often have rigorous quality control processes and a history of producing reliable components.

B. Quality Assurance Standards

Look for capacitors that meet industry quality assurance standards, such as ISO 9001 or AEC-Q200 for automotive applications. These standards ensure that the components have undergone thorough testing and meet specific performance criteria.

C. Testing and Certification

Consider capacitors that have been tested and certified by recognized organizations. This can provide additional assurance of their reliability and performance in your application.

VI. Application-Specific Considerations

A. Consumer Electronics

In consumer electronics, capacitors are often used for power supply filtering and signal coupling. High capacitance values and low ESR are typically desired for these applications.

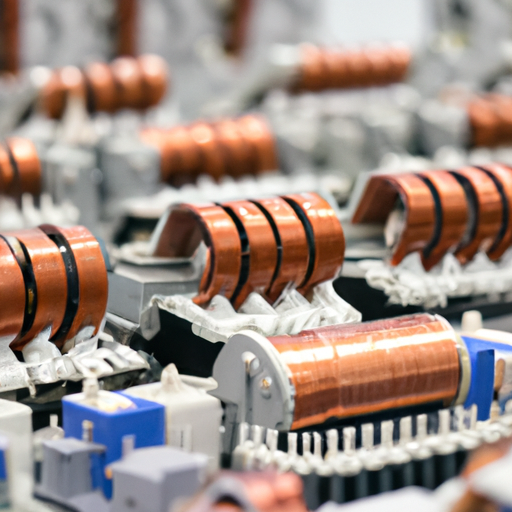

B. Industrial Applications

Industrial applications may require capacitors that can withstand harsh environments and high ripple currents. Selecting capacitors with robust construction and high reliability is essential.

C. Automotive and Aerospace

In automotive and aerospace applications, capacitors must meet stringent safety and reliability standards. Consider capacitors that are specifically designed for these demanding environments.

D. Medical Devices

Medical devices require capacitors that are highly reliable and compliant with medical standards. Selecting capacitors with long lifetimes and low failure rates is critical in these applications.

VII. Tools and Resources for Selection

A. Datasheets and Technical Specifications

Always refer to the datasheets and technical specifications provided by manufacturers. These documents contain essential information about the capacitor's characteristics, ratings, and recommended applications.

B. Online Calculators and Selection Tools

Many manufacturers offer online calculators and selection tools to help you choose the right capacitor for your application. These tools can simplify the selection process and ensure you consider all relevant factors.

C. Consultation with Engineers and Experts

When in doubt, consult with engineers or experts in the field. Their experience and knowledge can provide valuable insights and help you make informed decisions.

VIII. Conclusion

Selecting the right aluminum electrolytic capacitor is a critical step in ensuring the performance and reliability of electronic circuits. By considering factors such as capacitance value, voltage rating, ESR, temperature, and application-specific needs, you can make informed choices that meet the requirements of your projects. Additionally, staying informed about new technologies and trends in capacitor design will help you adapt to the evolving landscape of electronics. Remember, thorough selection is key to achieving optimal performance and longevity in your electronic devices.

IX. References

A. Suggested Reading

- "Capacitor Technology and Applications" by John Smith

- "Electrolytic Capacitors: Theory and Practice" by Jane Doe

B. Industry Standards and Guidelines

- IEC 60384: Fixed capacitors for use in electronic equipment

- AEC-Q200: Qualification of Passive Components for Automotive Applications

C. Manufacturer Websites and Resources

- [Panasonic Capacitors](https://www.panasonic.com)

- [Nichicon Corporation](https://www.nichicon.co.jp)

- [KEMET Electronics](https://www.kemet.com)

This comprehensive guide provides a detailed overview of the selection process for aluminum electrolytic capacitors, ensuring that you are well-equipped to make informed decisions for your electronic designs.