What are the product standards for the role of resistors?

What are the Product Standards for the Role of Resistors?

I. Introduction

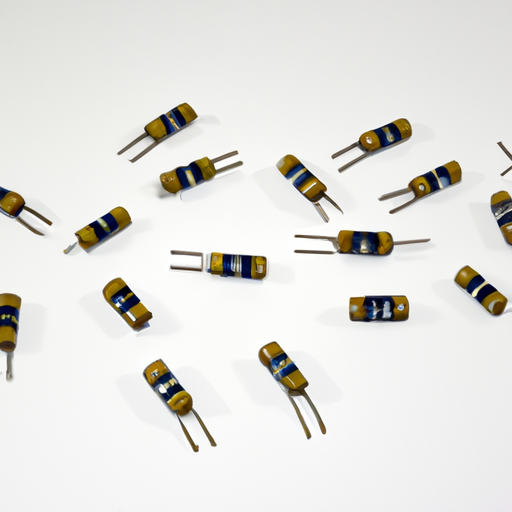

A. Definition of Resistors

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage and current levels, ensuring that electronic devices operate safely and effectively. By providing a specific resistance value, resistors help to manage the electrical characteristics of circuits, making them fundamental to the design and functionality of electronic systems.

B. Importance of Resistors in Electronic Circuits

In electronic circuits, resistors play a crucial role in various applications, including voltage division, current limiting, and signal conditioning. They are used in everything from simple circuits to complex devices, such as computers and smartphones. Without resistors, circuits would be prone to excessive current flow, leading to component damage and circuit failure. Thus, understanding the product standards for resistors is vital for engineers and manufacturers to ensure reliability and performance.

C. Overview of Product Standards

Product standards for resistors are established guidelines that ensure the quality, safety, and performance of these components. These standards are developed by various international organizations and are essential for manufacturers to comply with to meet market demands and regulatory requirements. This blog post will explore the types of resistors, key product standards, electrical characteristics, environmental considerations, quality control, and applications.

II. Types of Resistors

A. Fixed Resistors

Fixed resistors have a constant resistance value and are the most common type used in electronic circuits. They come in various materials and constructions, including:

1. **Carbon Composition Resistors**: Made from a mixture of carbon and a binding material, these resistors are known for their high energy absorption and are often used in high-power applications.

2. **Metal Film Resistors**: These resistors are made by depositing a thin layer of metal onto a ceramic substrate. They offer high precision and stability, making them suitable for applications requiring accurate resistance values.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a core, wirewound resistors can handle high power levels and are often used in power applications.

B. Variable Resistors

Variable resistors allow for adjustable resistance values, making them versatile components in electronic circuits. They include:

1. **Potentiometers**: Used for adjusting voltage levels in circuits, potentiometers are commonly found in volume controls and other user-adjustable settings.

2. **Rheostats**: Similar to potentiometers but designed to handle higher currents, rheostats are used for applications like dimming lights or controlling motor speeds.

C. Specialty Resistors

Specialty resistors are designed for specific applications and include:

1. **Thermistors**: Temperature-sensitive resistors that change resistance with temperature variations, thermistors are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure and are commonly used in light-sensing applications.

III. Key Product Standards for Resistors

A. International Standards Organizations

Several international organizations develop and maintain standards for resistors, including:

1. **International Electrotechnical Commission (IEC)**: The IEC sets global standards for electrical and electronic devices, including resistors.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE develops standards for a wide range of electrical and electronic technologies, including specifications for resistors.

3. **American National Standards Institute (ANSI)**: ANSI oversees the development of standards for various industries in the United States, including those related to resistors.

B. Key Standards and Specifications

Some of the key standards and specifications for resistors include:

1. **IEC 60115 - Fixed Resistors**: This standard outlines the requirements for fixed resistors, including performance, testing methods, and reliability.

2. **MIL-PRF-55182 - Thin Film Resistors**: A military specification that defines the performance and reliability requirements for thin film resistors used in military applications.

3. **EIA-198 - Resistor Color Code**: This standard provides a color-coding system for identifying resistor values, ensuring consistency and ease of use in circuit design.

C. Compliance and Certification

1. Importance of Compliance

Compliance with product standards is crucial for manufacturers to ensure that their resistors meet safety and performance requirements. Non-compliance can lead to product failures, safety hazards, and legal liabilities.

2. Certification Processes

Manufacturers often seek certification from recognized organizations to demonstrate compliance with relevant standards. This process typically involves rigorous testing and evaluation of products to ensure they meet established criteria.

IV. Electrical Characteristics of Resistors

Understanding the electrical characteristics of resistors is essential for selecting the right component for a specific application. Key characteristics include:

A. Resistance Value

The resistance value, measured in ohms (Ω), determines how much current will flow through the resistor when a voltage is applied. Selecting the correct resistance value is critical for circuit functionality.

B. Tolerance

Tolerance indicates the allowable deviation from the specified resistance value. It is expressed as a percentage and is crucial for applications requiring precise resistance values.

C. Temperature Coefficient

The temperature coefficient measures how much a resistor's resistance changes with temperature. A low temperature coefficient is desirable for applications requiring stable performance across varying temperatures.

D. Power Rating

The power rating, measured in watts (W), indicates the maximum power a resistor can dissipate without overheating. Selecting a resistor with an appropriate power rating is essential to prevent damage.

E. Voltage Rating

The voltage rating specifies the maximum voltage that can be applied across a resistor without causing breakdown or failure. It is important to choose resistors with voltage ratings suitable for the intended application.

V. Environmental and Mechanical Standards

A. Temperature and Humidity Testing

Resistors must be tested for performance under various temperature and humidity conditions to ensure reliability in different environments. This testing helps identify potential failures due to environmental factors.

B. Mechanical Shock and Vibration

Resistors used in applications subject to mechanical shock and vibration must meet specific standards to ensure they can withstand these conditions without failure.

C. RoHS Compliance

The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electronic components. Compliance with RoHS is essential for manufacturers to meet environmental regulations.

D. Environmental Impact Considerations

Manufacturers are increasingly focused on minimizing the environmental impact of their products. This includes using sustainable materials and processes in resistor production.

VI. Quality Control and Testing Procedures

A. Incoming Inspection

Quality control begins with incoming inspection, where raw materials and components are evaluated for compliance with specifications before production.

B. In-Process Testing

During manufacturing, in-process testing ensures that resistors meet performance standards at various stages of production.

C. Final Product Testing

Final product testing verifies that the finished resistors meet all specified standards and performance criteria before they are shipped to customers.

D. Reliability Testing

Reliability testing assesses the long-term performance of resistors under various conditions, helping manufacturers identify potential issues before products reach the market.

VII. Applications of Resistors

A. Consumer Electronics

Resistors are widely used in consumer electronics, including smartphones, televisions, and audio equipment, to control current and voltage levels.

B. Industrial Applications

In industrial settings, resistors are used in control systems, automation, and power management applications, ensuring safe and efficient operation.

C. Automotive Electronics

Automotive applications rely on resistors for various functions, including sensor calibration, power management, and control systems.

D. Medical Devices

In medical devices, precision and reliability are critical. Resistors are used in diagnostic equipment, monitoring devices, and therapeutic applications to ensure accurate performance.

VIII. Conclusion

A. Summary of Key Points

Resistors are essential components in electronic circuits, and understanding their product standards is crucial for ensuring safety, reliability, and performance. From fixed and variable resistors to specialty types, each has specific standards and characteristics that must be considered in design and manufacturing.

B. The Future of Resistor Standards

As technology advances, the standards governing resistors will continue to evolve. Manufacturers must stay informed about changes in regulations and industry best practices to remain competitive and compliant.

C. Importance of Adhering to Standards for Safety and Performance

Adhering to product standards is vital for manufacturers to ensure the safety and performance of their resistors. By following established guidelines, manufacturers can produce high-quality components that meet the demands of various applications.

IX. References

A. List of Standards and Guidelines

1. IEC 60115 - Fixed Resistors

2. MIL-PRF-55182 - Thin Film Resistors

3. EIA-198 - Resistor Color Code

B. Relevant Literature and Resources

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John L. Hennessy

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

This comprehensive overview of product standards for resistors highlights their importance in electronic circuits and the need for compliance with established guidelines to ensure safety and performance. Understanding these standards is essential for engineers, manufacturers, and anyone involved in the design and production of electronic components.