Latest Current Sensing Resistor Specifications

Latest Current Sensing Resistor Specifications

I. Introduction

A. Definition of Current Sensing Resistors

Current sensing resistors, often referred to as shunt resistors, are specialized resistive components designed to measure the flow of electric current in a circuit. By introducing a known resistance into the circuit, these resistors allow for the calculation of current based on the voltage drop across them, following Ohm's Law (V = IR).

B. Importance of Current Sensing in Electrical Applications

The ability to accurately measure current is crucial in various electrical applications, from power management systems to battery monitoring and motor control. Current sensing resistors play a vital role in ensuring the efficiency and safety of electronic devices by providing real-time feedback on current levels, enabling better control and protection mechanisms.

C. Overview of the Document's Purpose and Scope

This document aims to provide an in-depth understanding of the latest specifications for current sensing resistors, including their functionality, key specifications, performance characteristics, material considerations, recent innovations, and guidance on selecting the right resistor for specific applications.

II. Understanding Current Sensing Resistors

A. What are Current Sensing Resistors?

1. Basic Functionality

Current sensing resistors operate by creating a small voltage drop proportional to the current flowing through them. This voltage drop can be measured and used to calculate the current, making them essential for monitoring and controlling electrical systems.

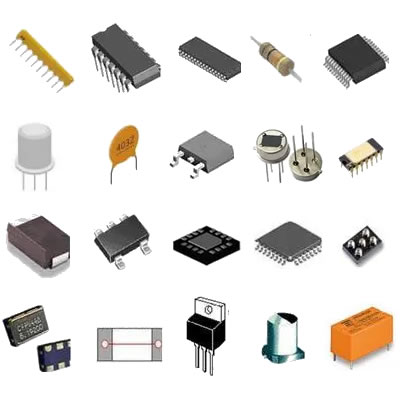

2. Types of Current Sensing Resistors

There are several types of current sensing resistors, including:

Shunt Resistors: These are low-resistance resistors placed in series with the load to measure current.

Current Sense Amplifiers: These devices combine a resistor with an amplifier to enhance the voltage signal for better accuracy.

Integrated Current Sensors: These combine sensing and signal processing in a single package, offering compact solutions for current measurement.

B. Applications of Current Sensing Resistors

1. Power Management

In power management systems, current sensing resistors help monitor power consumption, enabling efficient energy use and preventing overload conditions.

2. Battery Management Systems

In battery management systems, these resistors are crucial for monitoring charge and discharge currents, ensuring battery health and longevity.

3. Motor Control

Current sensing is vital in motor control applications, where it helps regulate motor performance and protect against overcurrent conditions.

4. Renewable Energy Systems

In renewable energy systems, such as solar inverters, current sensing resistors are used to optimize energy conversion and monitor system performance.

III. Key Specifications of Current Sensing Resistors

A. Resistance Value

1. Ohmic Value Range

Current sensing resistors typically have low resistance values, often in the milliohm range, to minimize power loss while still providing accurate current measurements.

2. Tolerance Levels

Tolerance levels indicate the precision of the resistor's value, with common tolerances ranging from ±1% to ±5%, depending on the application requirements.

B. Power Rating

1. Definition and Importance

The power rating of a current sensing resistor indicates the maximum power it can dissipate without overheating. This specification is critical for ensuring reliability and performance in high-current applications.

2. Common Power Ratings in Current Sensing Resistors

Power ratings for current sensing resistors can vary widely, with common ratings ranging from 0.1W to several watts, depending on the size and application.

C. Temperature Coefficient

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for maintaining accuracy across varying temperatures.

2. Impact on Performance

A high temperature coefficient can lead to significant measurement errors, especially in applications with fluctuating temperatures, making it essential to select resistors with suitable specifications.

D. Size and Form Factor

1. Common Packages (e.g., SMD, Through-Hole)

Current sensing resistors come in various packages, including surface-mount devices (SMD) and through-hole types. The choice of package affects the resistor's thermal performance and ease of integration into circuits.

2. Importance of Size in Design

The size of the resistor can impact the overall design of the circuit, especially in compact applications where space is limited. Smaller resistors can help reduce the footprint of the design.

E. Voltage Rating

1. Definition and Relevance

The voltage rating indicates the maximum voltage that can be applied across the resistor without causing breakdown or failure. This specification is crucial for ensuring safe operation in high-voltage applications.

2. Typical Voltage Ratings for Different Applications

Voltage ratings for current sensing resistors can range from a few volts to several hundred volts, depending on the specific application and design requirements.

IV. Performance Characteristics

A. Linearity and Accuracy

1. Importance of Linearity in Measurements

Linearity refers to the ability of the resistor to provide a consistent voltage drop across a range of current levels. High linearity is essential for accurate current measurements.

2. Factors Affecting Accuracy

Factors such as temperature variations, resistor tolerance, and circuit design can all impact the accuracy of current measurements, making it important to consider these elements during design.

B. Frequency Response

1. Definition and Relevance

Frequency response refers to how well the resistor can perform at different frequencies. This characteristic is particularly important in high-frequency applications, where signal integrity is critical.

2. Impact on High-Frequency Applications

In high-frequency applications, poor frequency response can lead to inaccurate measurements and signal distortion, necessitating careful selection of current sensing resistors.

C. Noise Performance

1. Sources of Noise in Current Sensing

Noise can arise from various sources, including thermal noise, electromagnetic interference, and circuit layout. Understanding these sources is crucial for minimizing their impact on measurements.

2. Techniques to Minimize Noise

Techniques such as proper grounding, shielding, and using low-noise components can help reduce noise levels and improve the overall performance of current sensing circuits.

V. Material Considerations

A. Common Materials Used in Current Sensing Resistors

1. Metal Film

Metal film resistors offer high precision and stability, making them suitable for applications requiring accurate current measurements.

2. Wirewound

Wirewound resistors are known for their high power ratings and low inductance, making them ideal for high-current applications.

3. Thick Film

Thick film resistors are cost-effective and widely used in various applications, although they may have lower precision compared to metal film resistors.

B. Advantages and Disadvantages of Each Material Type

Each material type has its advantages and disadvantages, with metal film offering high precision, wirewound providing high power handling, and thick film being cost-effective but less precise.

C. Environmental Considerations

1. RoHS Compliance

Many current sensing resistors are designed to be RoHS compliant, ensuring they meet environmental regulations regarding hazardous substances.

2. Thermal Stability

Thermal stability is crucial for maintaining performance across varying temperatures, making it an important consideration in material selection.

VI. Recent Innovations and Trends

A. Advances in Technology

1. Miniaturization of Components

Recent advancements in technology have led to the miniaturization of current sensing resistors, allowing for more compact designs without sacrificing performance.

2. Enhanced Thermal Management

Innovations in thermal management techniques have improved the performance and reliability of current sensing resistors, particularly in high-power applications.

B. Emerging Applications

1. Electric Vehicles

The rise of electric vehicles has created a demand for advanced current sensing solutions to monitor battery performance and optimize energy usage.

2. IoT Devices

As the Internet of Things (IoT) continues to grow, current sensing resistors are increasingly being integrated into smart devices for real-time monitoring and control.

C. Future Directions in Current Sensing Resistor Development

Future developments in current sensing resistors are likely to focus on improving accuracy, reducing size, and enhancing thermal performance to meet the demands of emerging technologies.

VII. Selecting the Right Current Sensing Resistor

A. Factors to Consider

1. Application Requirements

When selecting a current sensing resistor, it is essential to consider the specific requirements of the application, including current range, voltage levels, and environmental conditions.

2. Environmental Conditions

Factors such as temperature, humidity, and potential exposure to contaminants should also be taken into account to ensure reliable performance.

B. Common Mistakes to Avoid

Common mistakes in selecting current sensing resistors include overlooking power ratings, failing to consider temperature coefficients, and not accounting for noise performance.

C. Resources for Further Research

For further research, engineers can refer to manufacturer datasheets, industry standards, and academic journals to gain insights into the latest developments and best practices in current sensing technology.

VIII. Conclusion

A. Recap of Key Points

Current sensing resistors are essential components in modern electrical applications, providing critical measurements for power management, battery systems, and motor control. Understanding their specifications, performance characteristics, and material considerations is vital for selecting the right resistor for specific applications.

B. The Importance of Staying Updated with Specifications

As technology continues to evolve, staying updated with the latest specifications and innovations in current sensing resistors is crucial for engineers and designers to ensure optimal performance and reliability.

C. Final Thoughts on the Future of Current Sensing Resistors

The future of current sensing resistors looks promising, with ongoing advancements in technology and increasing demand across various industries. By understanding the latest specifications and trends, professionals can make informed decisions that enhance the performance of their electrical systems.

IX. References

A. Academic Journals

- IEEE Transactions on Power Electronics

- Journal of Electronic Materials

B. Industry Standards and Guidelines

- IEC 60115-1: Fixed Resistors for Use in Electronic Equipment

- AEC-Q200: Stress Test Qualification for Passive Components

C. Manufacturer Specifications and Datasheets

- Vishay Precision Group

- Ohmite Manufacturing Company

This comprehensive overview of current sensing resistors provides valuable insights into their specifications, applications, and the latest trends in the industry, serving as a useful resource for engineers and designers alike.