What are the product characteristics of ceramic capacitors?

Product Characteristics of Ceramic Capacitors

I. Introduction

A. Definition of Ceramic Capacitors

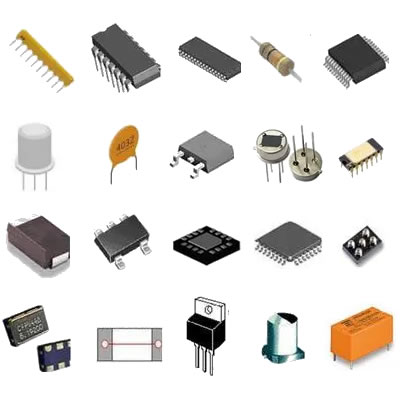

Ceramic capacitors are passive electronic components that store electrical energy in an electric field. They are made from ceramic materials that act as dielectric insulators, allowing them to maintain a charge. These capacitors are widely used in various electronic circuits due to their reliability and performance.

B. Importance of Ceramic Capacitors in Electronics

Ceramic capacitors play a crucial role in modern electronics, serving functions such as filtering, decoupling, and energy storage. Their ability to operate at high frequencies and their compact size make them ideal for applications in consumer electronics, automotive systems, and telecommunications.

C. Purpose of the Article

This article aims to provide a comprehensive overview of the product characteristics of ceramic capacitors, including their types, physical and electrical properties, performance metrics, advantages, limitations, and applications.

II. Types of Ceramic Capacitors

A. Class 1 Ceramic Capacitors

Class 1 ceramic capacitors are known for their stability and low loss characteristics. They are typically made from materials like titanium dioxide and are used in applications where precision is critical.

1. Characteristics

Class 1 capacitors exhibit minimal capacitance change with temperature and voltage variations. They have low dielectric losses and high insulation resistance.

2. Applications

These capacitors are commonly used in timing circuits, oscillators, and RF applications where stability is paramount.

B. Class 2 Ceramic Capacitors

Class 2 ceramic capacitors, on the other hand, offer higher capacitance values but with less stability compared to Class 1. They are made from materials like barium titanate.

1. Characteristics

Class 2 capacitors have a higher dielectric constant, which allows for greater capacitance in a smaller package. However, they are more sensitive to temperature and voltage changes.

2. Applications

These capacitors are widely used in power supply circuits, coupling, and decoupling applications where size and capacitance are more critical than precision.

C. Comparison between Class 1 and Class 2

In summary, Class 1 capacitors are preferred for applications requiring stability and precision, while Class 2 capacitors are chosen for their higher capacitance values and compact size.

III. Physical Characteristics

A. Material Composition

1. Dielectric Materials

The dielectric material in ceramic capacitors is crucial for their performance. Class 1 capacitors typically use titanium dioxide, while Class 2 capacitors use barium titanate, which provides a higher dielectric constant.

2. Conductive Materials

The conductive plates of ceramic capacitors are usually made from metals like silver or nickel, which ensure efficient charge storage and discharge.

B. Size and Form Factors

1. Surface Mount vs. Through-Hole

Ceramic capacitors come in various form factors, including surface mount (SMD) and through-hole types. SMD capacitors are favored in modern electronics for their compact size and ease of automated assembly.

2. Standard Sizes and Custom Options

They are available in standard sizes defined by industry standards, but custom sizes can also be manufactured to meet specific design requirements.

C. Voltage Ratings

1. Breakdown Voltage

The breakdown voltage is the maximum voltage that a capacitor can withstand before it fails. Ceramic capacitors typically have high breakdown voltages, making them suitable for high-voltage applications.

2. Derating Guidelines

It is recommended to derate ceramic capacitors by 50% of their rated voltage to enhance reliability and longevity, especially in high-stress environments.

IV. Electrical Characteristics

A. Capacitance Values

1. Range of Capacitance

Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), catering to various applications.

2. Tolerance Levels

Tolerance levels for ceramic capacitors can vary, with Class 1 capacitors typically offering tighter tolerances compared to Class 2.

B. Temperature Coefficient

1. Types of Temperature Coefficients

The temperature coefficient indicates how capacitance changes with temperature. Class 1 capacitors have a temperature coefficient of ±30 ppm/°C, while Class 2 capacitors can vary significantly.

2. Impact on Performance

Understanding the temperature coefficient is essential for applications where temperature fluctuations are expected, as it directly affects circuit performance.

C. Frequency Response

1. Self-Resonant Frequency

Ceramic capacitors have a self-resonant frequency, beyond which their impedance decreases. This frequency is critical in high-frequency applications.

2. Impedance Characteristics

The impedance of ceramic capacitors varies with frequency, making them suitable for filtering applications where specific frequency responses are required.

V. Performance Characteristics

A. Stability and Reliability

1. Aging Effects

Ceramic capacitors can experience aging effects, particularly Class 2 types, where capacitance may decrease over time. Understanding these effects is crucial for long-term reliability.

2. Failure Mechanisms

Common failure mechanisms include dielectric breakdown and mechanical stress, which can lead to capacitor failure in high-stress environments.

B. Temperature and Voltage Behavior

1. Temperature Coefficient of Capacitance (TCC)

The TCC indicates how capacitance changes with temperature. A low TCC is desirable for applications requiring stable performance across temperature variations.

2. Voltage Coefficient of Capacitance (VCC)

The VCC describes how capacitance changes with applied voltage. Class 2 capacitors can exhibit significant changes in capacitance under varying voltage conditions.

C. Dielectric Absorption and Loss

1. Dissipation Factor

The dissipation factor measures the energy loss in a capacitor. Lower values indicate better performance, making this an important characteristic for high-frequency applications.

2. Impact on Circuit Performance

High dielectric absorption can lead to delayed discharge times, affecting circuit performance, particularly in timing applications.

VI. Advantages of Ceramic Capacitors

A. High Dielectric Strength

Ceramic capacitors can withstand high voltages, making them suitable for demanding applications.

B. Small Size and Lightweight

Their compact size allows for space-saving designs in modern electronics, which is particularly important in portable devices.

C. Wide Range of Capacitance Values

The availability of various capacitance values makes ceramic capacitors versatile for different applications.

D. Low Equivalent Series Resistance (ESR)

Low ESR contributes to efficient performance in high-frequency applications, reducing energy loss.

E. Cost-Effectiveness

Ceramic capacitors are generally more affordable than other capacitor types, making them a popular choice in cost-sensitive applications.

VII. Limitations of Ceramic Capacitors

A. Non-Linear Capacitance Behavior

Class 2 capacitors can exhibit non-linear capacitance behavior, which may not be suitable for precision applications.

B. Limited Capacitance Values for Class 1

Class 1 capacitors have a limited range of capacitance values, which may restrict their use in certain applications.

C. Sensitivity to Voltage and Temperature Changes

Class 2 capacitors are sensitive to voltage and temperature changes, which can affect their performance in varying conditions.

D. Mechanical Fragility

Ceramic capacitors can be mechanically fragile, making them susceptible to damage during handling and assembly.

VIII. Applications of Ceramic Capacitors

A. Consumer Electronics

Ceramic capacitors are widely used in smartphones, tablets, and other consumer electronics for decoupling and filtering applications.

B. Automotive Applications

In automotive systems, ceramic capacitors are used for power management, signal processing, and noise filtering.

C. Industrial Equipment

They are employed in industrial machinery for timing, filtering, and energy storage applications.

D. Telecommunications

Ceramic capacitors are essential in telecommunications equipment for signal integrity and noise reduction.

E. Medical Devices

In medical devices, reliability and stability are critical, making ceramic capacitors a preferred choice for various applications.

IX. Conclusion

A. Summary of Key Characteristics

Ceramic capacitors are versatile components with a range of characteristics that make them suitable for various applications. Understanding their types, physical and electrical properties, and performance metrics is essential for selecting the right capacitor for a specific application.

B. Future Trends in Ceramic Capacitor Technology

As technology advances, the demand for smaller, more efficient capacitors will continue to grow. Innovations in materials and manufacturing processes are expected to enhance the performance and reliability of ceramic capacitors.

C. Final Thoughts on the Importance of Understanding Product Characteristics

A thorough understanding of ceramic capacitors' product characteristics is vital for engineers and designers to make informed decisions in their electronic designs. As the electronics industry evolves, staying updated on these characteristics will ensure optimal performance and reliability in future applications.

X. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Standards

- IEC 60384-14: Fixed capacitors for use in electronic equipment

- EIA-198: Standard for Ceramic Capacitors

C. Manufacturer Specifications

- Murata Manufacturing Co., Ltd.

- KEMET Corporation

D. Relevant Books and Articles

- "Capacitors: Technology and Trends" by John Smith

- "Understanding Capacitors" by Jane Doe

This comprehensive overview of ceramic capacitors highlights their significance in modern electronics, providing insights into their characteristics, advantages, limitations, and applications. Understanding these factors is essential for anyone involved in electronic design and engineering.