陶瓷电阻器产品都有哪些优势?

System

Sep 17

0

陶瓷电阻产品的优势是什么?

I. 引言

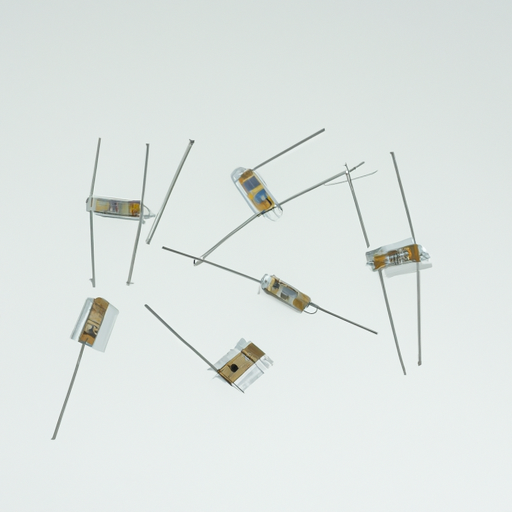

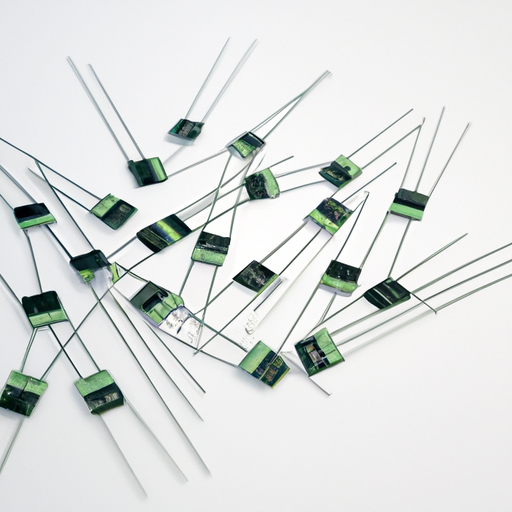

在电子世界中,电阻器在控制电流流动方面起着关键作用。在各种类型的电阻器中,陶瓷电阻器因其独特的性能和优势而脱颖而出。陶瓷电阻器由陶瓷材料和导电元素组成,提供了一系列使其适用于各种应用的优势。本文旨在探讨陶瓷电阻产品的优势,它们的组成、制造过程、应用以及与其他电阻器类型的比较。

II. 陶瓷电阻器的组成和制造

A. 陶瓷电阻器中使用的材料

陶瓷电阻器主要由陶瓷材料组成,这些材料提供了优秀的热电性能。最常见的陶瓷类型包括氧化铝和氧化锆。氧化铝以其高热稳定性和电绝缘性而闻名,常常是许多陶瓷电阻器的首选材料。另一方面,氧化锆提供了卓越的机械强度,在需要增强耐久性的应用中使用。

除了陶瓷,还融入了导电材料,如金属氧化物,这些材料对于创建决定电阻器值的电阻元件至关重要。

B. 制造过程

陶瓷电阻器的制造涉及几个关键过程,包括烧结和印刷技术。烧结是一种将陶瓷粉末加热至低于其熔点的温度,使颗粒粘结在一起形成固态结构的过程。这个过程增强了电阻器的机械强度和热稳定性。

印刷技术,如丝网印刷或喷墨印刷,用于将电阻材料涂覆在陶瓷基板上。这些方法允许精确控制电阻器的尺寸和电阻值。

C. 质量控制措施

在陶瓷电阻器的生产中,质量控制至关重要,以确保其可靠性和性能。制造商实施严格的测试程序,包括电气测试、热循环和机械应力测试,以验证电阻器符合行业标准和规格。

III. 陶瓷电阻产品的主要优势

A. 高热稳定性

陶瓷电阻器最显著的优势之一是其高热稳定性。它们可以在不牺牲性能的情况下承受极端的温度波动。这一特性使它们适用于高温环境,如汽车和工业设置,其他类型的电阻器可能会失效。

B. 优秀的电气绝缘性

陶瓷电阻器提供了优秀的电气绝缘性能,导致漏电流低和介电强度高。在需要保持信号完整性敏感的电子应用中,这一特点尤为重要。防止不必要的电流流动增强了电子电路的整体性能和可靠性。

What kind of product is resistor wiring?

System

Jan 14

0

What Kind of Product is Resistor Wiring?

I. Introduction

In the world of electronics, resistors play a crucial role in the functionality and efficiency of electrical circuits. Resistor wiring, a term that encompasses the various configurations and applications of resistors in circuits, is fundamental to understanding how electronic devices operate. This article aims to provide a comprehensive overview of resistor wiring, exploring its definition, types, applications, materials, and the importance it holds in circuit design. By the end, readers will have a clearer understanding of resistor wiring and its significance in the ever-evolving field of electronics.

II. Understanding Resistors

A. What is a Resistor?

A resistor is a passive electronic component that limits the flow of electric current in a circuit. Its primary function is to provide resistance, which is measured in ohms (Ω). Resistors are essential for controlling voltage and current levels, ensuring that electronic components receive the appropriate amounts of power.

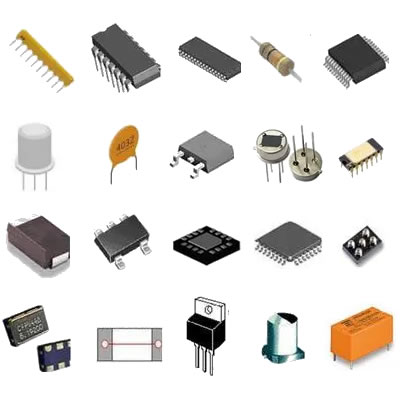

There are several types of resistors, including:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in various applications.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow users to adjust the resistance value, making them ideal for applications like volume controls in audio devices.

B. The Role of Resistors in Electrical Circuits

Resistors serve multiple purposes in electrical circuits, including:

1. **Current Limiting**: By restricting the flow of current, resistors protect sensitive components from damage due to excessive current.

2. **Voltage Division**: Resistors can be used in voltage divider circuits to produce a specific output voltage from a higher input voltage.

3. **Signal Conditioning**: In analog circuits, resistors help shape and modify signals, ensuring they meet the required specifications for further processing.

III. Resistor Wiring Explained

A. What is Resistor Wiring?

Resistor wiring refers to the arrangement and connection of resistors within an electrical circuit. This wiring is crucial for achieving the desired electrical characteristics and ensuring the circuit functions as intended. Resistor wiring can involve various configurations, each serving different purposes.

B. Types of Resistor Wiring Configurations

1. **Series Wiring**: In a series configuration, resistors are connected end-to-end, and the total resistance is the sum of the individual resistances. This setup is useful for applications requiring a specific resistance value that cannot be achieved with a single resistor.

2. **Parallel Wiring**: In a parallel configuration, resistors are connected across the same voltage source, providing multiple paths for current to flow. The total resistance in a parallel circuit is less than the smallest individual resistor, making it ideal for applications where lower resistance is needed.

3. **Combination Wiring**: This configuration combines both series and parallel arrangements, allowing for more complex circuit designs. Combination wiring is often used in advanced electronic devices to achieve specific performance characteristics.

C. Applications of Resistor Wiring

Resistor wiring finds applications across various fields, including:

1. **Consumer Electronics**: Resistor wiring is prevalent in devices like televisions, smartphones, and audio equipment, where it helps regulate power and signal levels.

2. **Industrial Applications**: In industrial settings, resistors are used in control systems, automation, and machinery to ensure safe and efficient operation.

3. **Automotive Systems**: Resistor wiring is critical in automotive electronics, including engine control units, lighting systems, and infotainment systems, where precise voltage and current control is essential.

IV. Materials and Construction of Resistor Wiring

A. Common Materials Used in Resistors

The materials used in resistor construction significantly influence their performance and application. Common materials include:

1. **Carbon Composition**: These resistors are made from a mixture of carbon and a binding material. They are inexpensive and widely used but have a higher tolerance and temperature coefficient.

2. **Metal Film**: Metal film resistors offer better precision and stability than carbon composition resistors. They are commonly used in applications requiring high accuracy.

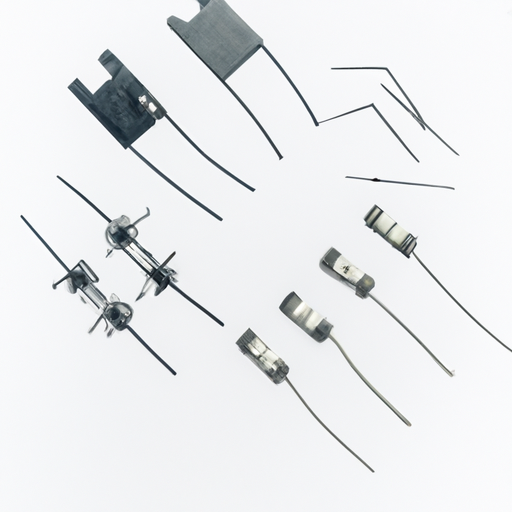

3. **Wire-Wound**: These resistors are made by winding a metal wire around a ceramic or plastic core. They can handle high power levels and are often used in power applications.

B. Construction Techniques

1. **Surface Mount Technology (SMT)**: SMT resistors are small and designed for automated assembly on circuit boards. They are widely used in modern electronics due to their compact size.

2. **Through-Hole Technology**: This traditional method involves inserting resistor leads through holes in a circuit board and soldering them in place. While less common in new designs, it is still used in many applications.

C. Factors Influencing Resistor Selection

When selecting resistors for a specific application, several factors must be considered:

1. **Resistance Value**: The required resistance value is determined by the circuit's design and functionality.

2. **Power Rating**: Resistors must be able to dissipate heat generated by the current flowing through them. The power rating indicates the maximum power a resistor can handle without failure.

3. **Tolerance and Temperature Coefficient**: Tolerance refers to the allowable deviation from the specified resistance value, while the temperature coefficient indicates how much the resistance changes with temperature. Both factors are crucial for ensuring circuit reliability.

V. The Importance of Resistor Wiring in Circuit Design

A. Impact on Circuit Performance

Resistor wiring significantly impacts the overall performance of a circuit. Properly designed resistor configurations contribute to:

1. **Stability and Reliability**: Well-chosen resistors help maintain stable voltage and current levels, ensuring the circuit operates reliably over time.

2. **Heat Dissipation**: Resistors generate heat during operation, and proper wiring can help manage this heat, preventing damage to components.

B. Design Considerations

When designing circuits, engineers must consider:

1. **Choosing the Right Resistor Values**: Selecting appropriate resistor values is critical for achieving the desired circuit performance.

2. **Layout and Placement in Circuits**: The physical arrangement of resistors can affect signal integrity and overall circuit efficiency.

C. Common Mistakes in Resistor Wiring

1. **Overheating**: Using resistors with insufficient power ratings can lead to overheating and failure, compromising circuit functionality.

2. **Incorrect Values Leading to Circuit Failure**: Miscalculating resistor values can result in circuit malfunctions, making it essential to double-check calculations during the design process.

VI. Innovations and Trends in Resistor Wiring

A. Advances in Resistor Technology

The field of resistor technology is continually evolving, with several notable advancements:

1. **Miniaturization and Integration**: As electronic devices become smaller, resistors are also being miniaturized, allowing for more compact circuit designs.

2. **Smart Resistors and Sensors**: Innovations in resistor technology have led to the development of smart resistors that can adapt their resistance based on environmental conditions, enhancing circuit performance.

B. Future Trends in Resistor Wiring

1. **Sustainability and Eco-Friendly Materials**: As the electronics industry moves towards sustainability, there is a growing interest in using eco-friendly materials in resistor manufacturing.

2. **The Role of Resistors in Emerging Technologies**: Resistors will continue to play a vital role in emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI), where precise control of electrical signals is essential.

VII. Conclusion

In summary, resistor wiring is a fundamental aspect of electrical circuit design, influencing performance, stability, and reliability. Understanding the various types of resistors, their configurations, and the materials used in their construction is essential for anyone involved in electronics. As technology continues to advance, the importance of resistor wiring will only grow, making it a critical area for further exploration and learning.

VIII. References

For those interested in delving deeper into the world of resistors and resistor wiring, the following resources are recommended:

1. "The Art of Electronics" by Paul Horowitz and Winfield Hill

2. "Electronic Principles" by Albert Malvino and David Bates

3. Industry standards and guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC).

By understanding the intricacies of resistor wiring, enthusiasts and professionals alike can enhance their knowledge and skills in the fascinating field of electronics.

Read more

What are the advantages of metal resistor products?

System

Jan 12

0

What are the Advantages of Metal Resistor Products?

I. Introduction

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. Among the various types of resistors available, metal resistors stand out due to their unique properties and advantages. Metal resistors, which include metal film, metal oxide, and wirewound resistors, are known for their precision, stability, and reliability. In this blog post, we will explore the advantages of metal resistor products, their types, applications, and future trends in technology.

II. Types of Metal Resistors

A. Metal Film Resistors

Metal film resistors are constructed using a thin layer of metal deposited on a ceramic substrate. This design allows for precise resistance values and excellent temperature stability. Common applications include audio equipment, precision measurement devices, and high-frequency circuits.

B. Metal Oxide Resistors

Metal oxide resistors utilize a metal oxide film as the resistive element. They are known for their high-temperature stability and ability to handle high power levels. These resistors are often used in power supplies and industrial applications where reliability is crucial.

C. Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. This construction allows for high power ratings and excellent heat dissipation. Wirewound resistors are commonly found in applications requiring high precision and stability, such as in laboratory equipment and power electronics.

III. Key Advantages of Metal Resistor Products

A. Precision and Accuracy

One of the most significant advantages of metal resistors is their precision and accuracy. Metal film resistors, for instance, can achieve tolerance levels as low as 0.1%, making them ideal for applications where exact resistance values are critical. Additionally, the temperature coefficient of resistance (TCR) in metal resistors is typically lower than in other types, ensuring that their performance remains stable across a wide temperature range.

B. Stability and Reliability

Metal resistors are known for their stability and reliability under varying environmental conditions. They maintain consistent performance over time, which is essential for applications in sensitive electronics and critical systems. The long-term stability of metal resistors reduces the need for frequent replacements, ultimately leading to lower maintenance costs.

C. Thermal Management

Effective thermal management is another advantage of metal resistors. Their construction allows for efficient heat dissipation, which is crucial in high-power applications. Metal resistors can operate within a wide temperature range, making them suitable for use in environments with fluctuating temperatures. This capability ensures that they can handle the thermal stresses associated with high current loads without degrading performance.

D. Low Noise Characteristics

Metal resistors exhibit low noise characteristics, which is particularly important in sensitive electronic applications. The low noise levels help maintain signal integrity, making metal resistors ideal for use in audio equipment, precision measurement devices, and communication systems. Their ability to minimize noise interference enhances overall circuit performance.

E. Wide Range of Values

Metal resistors are available in a wide range of resistance values, catering to various applications. Manufacturers often provide customization options, allowing engineers to specify exact resistance values and tolerances. This flexibility makes metal resistors suitable for diverse applications, from consumer electronics to industrial systems.

IV. Comparison with Other Resistor Types

A. Carbon Film Resistors

When comparing metal resistors to carbon film resistors, the differences in performance become evident. While carbon film resistors are generally less expensive, they do not offer the same level of precision and stability as metal resistors. Metal resistors are preferred in applications where accuracy is paramount, despite the higher cost.

B. Thin Film vs. Thick Film Resistors

Thin film resistors, which include metal film resistors, provide superior performance compared to thick film resistors. Thin film resistors offer better precision, lower noise, and improved temperature stability. While thick film resistors may be more cost-effective for certain applications, metal film resistors are often the better choice for high-performance circuits.

V. Applications of Metal Resistor Products

A. Consumer Electronics

In consumer electronics, metal resistors play a vital role in audio equipment, where precision and low noise are essential for high-quality sound reproduction. They are also used in power supplies to ensure stable voltage levels and reliable performance.

B. Industrial Applications

Metal resistors are widely used in industrial applications, particularly in automation and control systems. Their stability and reliability make them suitable for measurement and instrumentation, where accurate readings are critical for operational efficiency.

C. Automotive and Aerospace

In the automotive and aerospace industries, metal resistors are valued for their reliability in harsh environments. They are often used in safety-critical applications, such as braking systems and avionics, where failure is not an option. The ability of metal resistors to withstand extreme temperatures and vibrations makes them ideal for these demanding applications.

VI. Future Trends in Metal Resistor Technology

A. Innovations in Materials and Manufacturing

The future of metal resistor technology is likely to be shaped by innovations in materials and manufacturing processes. Advances in nanotechnology and new materials may lead to even more precise and stable resistors, further enhancing their performance in various applications.

B. Impact of Miniaturization on Design

As electronic devices continue to shrink in size, the demand for smaller, more efficient components will grow. Metal resistors are already being designed to meet these miniaturization trends, allowing them to fit into compact electronic devices without compromising performance.

C. Sustainability and Eco-Friendly Practices

Sustainability is becoming increasingly important in the electronics industry. Manufacturers are exploring eco-friendly practices in the production of metal resistors, including the use of recyclable materials and energy-efficient manufacturing processes. This trend aligns with the broader movement towards sustainable electronics and responsible consumption.

VII. Conclusion

In summary, metal resistor products offer numerous advantages, including precision, stability, thermal management, low noise characteristics, and a wide range of values. These benefits make them essential components in various applications, from consumer electronics to industrial systems and safety-critical environments. As technology continues to evolve, the future of metal resistors looks promising, with innovations in materials, miniaturization, and sustainability paving the way for even greater advancements. Selecting the right resistor for specific applications is crucial, and understanding the advantages of metal resistors can help engineers and designers make informed decisions.

VIII. References

1. Academic papers and articles on resistor technology and applications.

2. Industry standards and guidelines related to electronic components.

3. Manufacturer specifications and datasheets for various metal resistor products.

By understanding the advantages of metal resistors, engineers can leverage their unique properties to enhance the performance and reliability of electronic circuits, ensuring that they meet the demands of modern technology.

Read more

What is the function of a resistor? What important industry-related patents are included?

System

Jan 11

0

What is the Function of a Resistor? What Important Industry-Related Patents are Included?

I. Introduction

Resistors are fundamental components in electrical and electronic circuits, playing a crucial role in controlling the flow of electric current. Defined as passive two-terminal electrical components, resistors limit the amount of current that can pass through a circuit, thereby protecting sensitive components and ensuring proper functionality. Their importance cannot be overstated, as they are integral to a wide range of applications, from consumer electronics to industrial systems. This blog post will explore the function of resistors, their applications across various industries, and significant patents that have shaped resistor technology over the years.

II. The Function of a Resistor

A. Basic Principles of Resistance

At the heart of a resistor's function lies the concept of resistance, which is the opposition to the flow of electric current. This relationship is quantitatively described by Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. Mathematically, this is expressed as:

\[ V = I \times R \]

The unit of measurement for resistance is the ohm (Ω), named after the German physicist Georg Simon Ohm. Understanding these basic principles is essential for grasping how resistors operate within electrical circuits.

B. Role in Electrical Circuits

Resistors serve several critical functions in electrical circuits:

1. **Current Limiting**: By providing resistance, resistors limit the amount of current that can flow through a circuit. This is particularly important in protecting sensitive components, such as diodes and transistors, from excessive current that could lead to damage.

2. **Voltage Division**: Resistors can be used in voltage divider circuits to produce a specific output voltage that is a fraction of the input voltage. This is useful in applications where different components require different voltage levels.

3. **Signal Conditioning**: In analog circuits, resistors are often used to condition signals, ensuring that they are at the appropriate levels for processing. This includes filtering noise and adjusting signal amplitudes.

C. Types of Resistors

Resistors come in various types, each designed for specific applications:

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most common type used in circuits. They are available in various materials, including carbon, metal film, and wirewound.

2. **Variable Resistors (Potentiometers)**: These resistors allow for adjustable resistance values, making them ideal for applications such as volume controls in audio equipment.

3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which change resistance based on light exposure. These resistors are used in temperature sensing and light detection applications, respectively.

III. Applications of Resistors

Resistors are ubiquitous in modern technology, finding applications in various fields:

A. Consumer Electronics

In consumer electronics, resistors are essential components in devices such as audio equipment and home appliances. They help manage power levels, control sound output, and ensure the safe operation of devices.

B. Industrial Applications

In industrial settings, resistors play a vital role in automation systems and power distribution. They are used in control circuits to manage the operation of machinery and ensure the safe distribution of electrical power.

C. Automotive Industry

The automotive industry relies heavily on resistors for various applications, including engine control units and safety systems. Resistors help regulate electrical signals, ensuring that critical systems operate reliably and efficiently.

IV. Important Industry-Related Patents

A. Historical Overview of Resistor Patents

The development of resistor technology has been marked by numerous innovations, many of which have been protected by patents. These patents have played a significant role in advancing resistor technology and ensuring that inventors receive recognition for their contributions.

B. Notable Patents

1. **Patent for Carbon Composition Resistors**: One of the earliest patents in resistor technology, this innovation allowed for the mass production of resistors using carbon, which provided a stable and reliable resistance value.

2. **Patent for Wirewound Resistors**: This patent introduced a method for creating resistors by winding a wire around a core, allowing for higher power ratings and improved performance in various applications.

3. **Patent for Surface Mount Resistors**: As technology advanced, the need for smaller components led to the development of surface mount resistors, which are designed for automated assembly and are crucial for modern electronic devices.

C. Impact of Patents on Resistor Technology

The impact of these patents on resistor technology has been profound. They have led to advancements in performance, allowing for more precise and reliable resistors. Additionally, patents have influenced manufacturing processes, enabling the production of resistors that meet the demands of modern electronics.

V. Future Trends in Resistor Technology

As technology continues to evolve, so too does the field of resistor technology. Several trends are shaping the future of resistors:

A. Miniaturization and Integration

With the push for smaller and more efficient electronic devices, there is a growing trend toward miniaturization and integration of resistors into circuit designs. This allows for more compact devices without sacrificing performance.

B. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) is driving the development of smart resistors that can communicate and adapt to changing conditions. These resistors can enhance the functionality of connected devices, enabling more intelligent and responsive systems.

C. Sustainable Materials and Manufacturing Practices

As environmental concerns grow, there is an increasing focus on using sustainable materials and manufacturing practices in resistor production. This trend aims to reduce the environmental impact of electronic components while maintaining performance and reliability.

VI. Conclusion

In summary, resistors are essential components in electrical and electronic circuits, serving critical functions such as current limiting, voltage division, and signal conditioning. Their applications span various industries, from consumer electronics to automotive systems. The historical development of resistor technology has been significantly influenced by patents, which have driven advancements in performance and manufacturing processes. As we look to the future, trends such as miniaturization, smart technology, and sustainability will continue to shape the evolution of resistors, ensuring their relevance in an ever-changing technological landscape.

VII. References

- Academic Journals

- Industry Publications

- Patent Databases

This blog post provides a comprehensive overview of resistors, their functions, applications, and the importance of patents in their development. Understanding these elements is crucial for anyone interested in the field of electronics and electrical engineering.

Read more

What are the advantages of non-inductive resistor products?

System

Jan 11

0

What are the Advantages of Non-Inductive Resistor Products?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow and managing voltage levels. Among the various types of resistors available, non-inductive resistors stand out due to their unique construction and performance characteristics. This blog post aims to explore the advantages of non-inductive resistor products, highlighting their significance in modern electronic applications.

II. Understanding Non-Inductive Resistors

A. Explanation of Inductance in Resistors

Inductance is a property of electrical components that causes them to resist changes in current. In resistors, inductance can lead to unwanted effects, particularly in high-frequency applications. When current flows through a wire, it generates a magnetic field, which can induce voltage in nearby conductors. This phenomenon can distort signals and lead to inefficiencies in electronic circuits.

B. How Non-Inductive Resistors are Constructed

Non-inductive resistors are designed to minimize inductance by employing specific construction techniques. Typically, they are made using a wire-wound or film-based approach, where the winding is arranged in a way that cancels out the magnetic fields generated by the current. This careful arrangement allows non-inductive resistors to maintain a stable resistance value without the adverse effects of inductance.

C. Comparison with Inductive Resistors

In contrast, inductive resistors can introduce significant inductance, which can be detrimental in applications requiring high precision and stability. While inductive resistors may be suitable for low-frequency applications, they can cause phase shifts and signal degradation in high-frequency circuits. Non-inductive resistors, on the other hand, provide a more reliable solution for these demanding environments.

III. Key Advantages of Non-Inductive Resistor Products

A. Reduced Inductive Effects

1. Importance in High-Frequency Applications

One of the primary advantages of non-inductive resistors is their ability to minimize inductive effects. In high-frequency applications, such as RF (radio frequency) circuits, even small amounts of inductance can lead to significant signal distortion. Non-inductive resistors ensure that the integrity of the signal is maintained, making them ideal for use in these critical applications.

2. Impact on Signal Integrity

Maintaining signal integrity is paramount in modern electronics. Non-inductive resistors help achieve this by providing a stable resistance value without introducing unwanted phase shifts or distortions. This characteristic is particularly important in communication systems, where clear and accurate signal transmission is essential.

B. Improved Performance in AC Circuits

1. Stability of Resistance Values

Non-inductive resistors exhibit excellent stability in AC circuits. Unlike their inductive counterparts, which can experience fluctuations in resistance due to changing current conditions, non-inductive resistors maintain consistent performance. This stability is crucial for applications that require precise control over current and voltage levels.

2. Reduced Phase Shift

In AC circuits, phase shift can lead to inefficiencies and power losses. Non-inductive resistors minimize phase shift, allowing for better power factor correction and overall system efficiency. This advantage is particularly beneficial in power electronics, where optimizing performance is critical.

C. Enhanced Thermal Stability

1. Heat Dissipation Characteristics

Non-inductive resistors are designed to handle heat effectively. Their construction allows for better heat dissipation, reducing the risk of overheating and ensuring reliable operation even in demanding environments. This thermal stability is essential for applications where resistors are subjected to high power levels.

2. Reliability in High-Temperature Environments

In many industrial and automotive applications, components are exposed to elevated temperatures. Non-inductive resistors are built to withstand these conditions, providing reliable performance without degradation over time. This reliability is a significant advantage in applications where failure is not an option.

D. Lower Noise Generation

1. Importance in Sensitive Applications

Noise generation can be a critical issue in sensitive electronic applications, such as medical devices and precision measurement equipment. Non-inductive resistors produce significantly less noise compared to inductive resistors, ensuring that the performance of these sensitive systems is not compromised.

2. Impact on Overall System Performance

By minimizing noise, non-inductive resistors contribute to the overall performance of electronic systems. This advantage is particularly important in audio and RF applications, where clarity and fidelity are paramount. The reduced noise levels help maintain the quality of signals, leading to better overall system performance.

E. Versatility in Applications

1. Use in Precision Measurement Equipment

Non-inductive resistors are widely used in precision measurement equipment due to their stable resistance values and low noise generation. They are essential in applications where accuracy is critical, such as in laboratory instruments and calibration devices.

2. Applications in Audio and RF Circuits

In audio and RF circuits, non-inductive resistors are preferred for their ability to maintain signal integrity and minimize distortion. Their versatility makes them suitable for a wide range of applications, from high-fidelity audio systems to advanced communication devices.

IV. Specific Applications of Non-Inductive Resistors

A. Power Electronics

In power electronics, non-inductive resistors are used in various applications, including power supplies, inverters, and motor drives. Their ability to handle high power levels and maintain stability makes them ideal for these demanding environments.

B. Audio Equipment

Non-inductive resistors are commonly found in audio equipment, where they help maintain signal clarity and fidelity. They are used in amplifiers, equalizers, and other audio processing devices to ensure high-quality sound reproduction.

C. RF and Microwave Applications

In RF and microwave applications, non-inductive resistors are essential for maintaining signal integrity and minimizing losses. They are used in antennas, filters, and other RF components to ensure optimal performance.

D. Test and Measurement Instruments

Precision measurement instruments rely on non-inductive resistors for accurate readings. These resistors are used in oscilloscopes, multimeters, and other testing equipment to ensure reliable and precise measurements.

V. Considerations When Choosing Non-Inductive Resistors

A. Resistance Value and Tolerance

When selecting non-inductive resistors, it is essential to consider the required resistance value and tolerance. Different applications may require specific resistance levels, and choosing the right tolerance ensures that the resistor performs as expected.

B. Power Rating

The power rating of a resistor indicates how much power it can handle without overheating. It is crucial to select a non-inductive resistor with an appropriate power rating for the intended application to ensure reliability and performance.

C. Temperature Coefficient

The temperature coefficient of a resistor indicates how its resistance changes with temperature. Choosing a non-inductive resistor with a low temperature coefficient is essential for applications where temperature variations may occur.

D. Physical Size and Mounting Options

The physical size and mounting options of non-inductive resistors should also be considered. Depending on the application, different sizes and mounting configurations may be required to fit within the design constraints of the electronic system.

VI. Conclusion

In summary, non-inductive resistors offer numerous advantages that make them essential components in modern electronics. Their ability to reduce inductive effects, improve performance in AC circuits, enhance thermal stability, lower noise generation, and provide versatility in applications makes them a preferred choice for engineers and designers. As technology continues to evolve, the demand for non-inductive resistors is likely to grow, leading to advancements in their design and performance. Understanding the importance of non-inductive resistors is crucial for anyone involved in the field of electronics, as they play a vital role in ensuring the reliability and efficiency of electronic systems.

VII. References

- Academic Journals

- Industry Publications

- Manufacturer Specifications and Data Sheets

This blog post provides a comprehensive overview of the advantages of non-inductive resistor products, emphasizing their significance in various applications and the considerations for their selection.

Read more