What are the product standards for the main parameters of resistors?

What are the Product Standards for the Main Parameters of Resistors?

I. Introduction

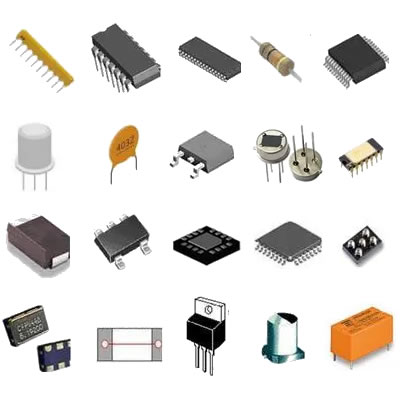

A. Definition of Resistors

Resistors are fundamental electronic components that limit the flow of electric current in a circuit. They are used in a variety of applications, from simple circuits to complex electronic devices. By providing a specific resistance, they help control voltage and current levels, ensuring that electronic components operate within their specified limits.

B. Importance of Resistor Standards

The performance and reliability of resistors are critical to the overall functionality of electronic devices. Therefore, adhering to established product standards is essential. These standards ensure that resistors meet specific performance criteria, which helps manufacturers produce reliable products and consumers to select components that will function as expected.

C. Overview of the Document

This blog post will explore the main parameters of resistors, the international standards governing these parameters, the classification of resistors, testing and quality assurance methods, applications of resistor standards, and the challenges and future trends in the industry.

II. Understanding Resistor Parameters

1. Definition and Measurement

The resistance value of a resistor is a measure of its opposition to the flow of electric current. It is determined by the material and dimensions of the resistor. Resistance is measured using an ohmmeter, which applies a known voltage and measures the resulting current to calculate resistance using Ohm's Law (V = IR).

2. Units of Measurement (Ohms)

Resistance is measured in ohms (Ω), named after the German physicist Georg Simon Ohm. The ohm is defined as the resistance between two points when a constant potential difference of one volt applied across those points produces a current of one ampere.

1. Definition and Importance

Tolerance indicates the allowable deviation from the specified resistance value. It is crucial for ensuring that resistors perform within acceptable limits, especially in precision applications.

2. Common Tolerance Values

Common tolerance values for resistors include ±1%, ±5%, and ±10%. Precision resistors may have tolerances as low as ±0.1%, making them suitable for high-accuracy applications.

1. Definition and Measurement

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. Exceeding this rating can lead to resistor failure.

2. Units of Measurement (Watts)

Power is measured in watts (W). Resistors are available in various power ratings, typically ranging from 1/8 W to several hundred watts, depending on their application.

1. Definition and Importance

The temperature coefficient of resistance (TCR) measures how much a resistor's resistance changes with temperature. This parameter is vital for applications where temperature fluctuations are expected.

2. Common Temperature Coefficient Values

TCR is expressed in parts per million per degree Celsius (ppm/°C). Common values range from ±50 ppm/°C for standard resistors to ±5 ppm/°C for precision resistors.

1. Definition and Importance

The voltage rating indicates the maximum voltage that can be applied across a resistor without risking breakdown or failure. This parameter is essential for ensuring safe operation in circuits.

2. Common Voltage Ratings

Voltage ratings for resistors can vary widely, from a few volts for small signal resistors to several kilovolts for high-voltage applications.

III. International Standards for Resistors

1. International Electrotechnical Commission (IEC)

The IEC develops international standards for electrical and electronic devices, including resistors. Their standards ensure compatibility and safety across different countries.

2. American National Standards Institute (ANSI)

ANSI oversees the development of voluntary consensus standards for products, services, processes, and systems in the United States, including those related to resistors.

3. Institute of Electrical and Electronics Engineers (IEEE)

IEEE is a leading organization in the development of standards for electrical and electronic engineering, including specifications for resistors used in various applications.

1. IEC 60115 Series

The IEC 60115 series outlines the general requirements for fixed resistors, including performance, testing methods, and classification.

2. ANSI/IEEE Standards

ANSI/IEEE standards provide guidelines for the performance and testing of resistors, ensuring they meet the necessary specifications for reliability and safety.

3. Other Relevant Standards

Other standards, such as those from the Joint Electron Device Engineering Council (JEDEC), also provide guidelines for specific types of resistors and their applications.

IV. Classification of Resistors

1. Carbon Composition Resistors

These resistors are made from a mixture of carbon and a binding material. They are known for their high tolerance and are often used in applications where high energy pulses are present.

2. Metal Film Resistors

Metal film resistors offer better stability and lower noise compared to carbon composition resistors. They are commonly used in precision applications.

3. Wirewound Resistors

Wirewound resistors are made by winding a metal wire around a ceramic or plastic core. They are capable of handling high power and are often used in power applications.

1. Potentiometers

Potentiometers are adjustable resistors that allow users to change the resistance value manually. They are commonly used in volume controls and other adjustable settings.

2. Rheostats

Rheostats are a type of variable resistor used to control current. They are often used in applications requiring high power.

1. Thermistors

Thermistors are temperature-sensitive resistors used for temperature measurement and control. They are widely used in temperature sensing applications.

2. Photoresistors

Photoresistors change their resistance based on light exposure. They are commonly used in light-sensing applications, such as automatic lighting systems.

V. Testing and Quality Assurance

1. Resistance Measurement

Resistance is measured using precision ohmmeters to ensure that the resistor meets its specified value.

2. Power Rating Testing

Power rating tests involve applying a specified voltage to the resistor and measuring the temperature rise to ensure it does not exceed the rated power.

3. Temperature Coefficient Testing

Temperature coefficient testing involves measuring the resistance at different temperatures to determine the TCR.

1. Compliance Testing

Compliance testing ensures that resistors meet the relevant international standards and specifications.

2. Reliability Testing

Reliability testing assesses the long-term performance of resistors under various environmental conditions.

3. Environmental Testing

Environmental testing evaluates how resistors perform under extreme conditions, such as high humidity, temperature fluctuations, and exposure to corrosive substances.

VI. Applications of Resistor Standards

A. Consumer Electronics

Resistor standards are crucial in consumer electronics, ensuring that devices operate safely and reliably.

B. Industrial Applications

In industrial settings, resistors are used in control systems, automation, and machinery, where adherence to standards is vital for safety and performance.

C. Automotive Industry

The automotive industry relies on resistors for various applications, including sensors and control systems, where standards ensure reliability and safety.

D. Medical Devices

In medical devices, precision and reliability are paramount. Resistor standards help ensure that these devices function correctly and safely.

VII. Challenges and Future Trends

A. Emerging Technologies and Their Impact on Resistor Standards

As technology advances, new materials and manufacturing processes are being developed, which may require updates to existing standards.

B. Sustainability and Environmental Considerations

There is a growing emphasis on sustainability in manufacturing processes, which may influence the materials and methods used in resistor production.

C. The Role of Digitalization in Resistor Manufacturing

Digitalization is transforming manufacturing processes, leading to improved efficiency and quality control in resistor production.

VIII. Conclusion

A. Summary of Key Points

Resistors are essential components in electronic circuits, and understanding their parameters and standards is crucial for ensuring their reliability and performance.

B. The Importance of Adhering to Standards

Adhering to established standards is vital for manufacturers and consumers alike, ensuring that resistors function as intended and meet safety requirements.

C. Future Outlook for Resistor Standards

As technology continues to evolve, resistor standards will need to adapt to new materials, applications, and manufacturing processes, ensuring that they remain relevant and effective.

IX. References

A. List of Standards and Guidelines

- IEC 60115 Series

- ANSI/IEEE Standards

- JEDEC Standards

B. Recommended Reading and Resources

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Components: A Complete Reference for Project Builders" by Charles Platt

This blog post provides a comprehensive overview of the product standards for resistors, highlighting their importance in various applications and the need for adherence to established guidelines. Understanding these standards is essential for anyone involved in electronics, from manufacturers to consumers.