Mainstream thin film resistor product series parameters

Mainstream Thin Film Resistor Product Series Parameters

I. Introduction

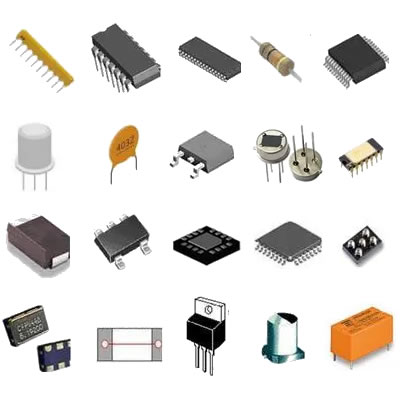

A. Definition of Thin Film Resistors

Thin film resistors are passive electronic components that provide resistance in a circuit. They are made by depositing a thin layer of resistive material onto a substrate, which can be made from various materials such as ceramic, glass, or silicon. The thin film technology allows for precise control over the resistance value, making these resistors ideal for applications requiring high accuracy and stability.

B. Importance of Thin Film Resistors in Electronics

Thin film resistors play a crucial role in modern electronics. Their high precision, low noise, and excellent temperature stability make them essential in applications ranging from consumer electronics to industrial automation. As electronic devices become more compact and complex, the demand for reliable and efficient components like thin film resistors continues to grow.

C. Overview of the Article's Purpose

This article aims to provide a comprehensive overview of the parameters and characteristics of mainstream thin film resistor products. By understanding these parameters, engineers and designers can make informed decisions when selecting resistors for their applications.

II. Understanding Thin Film Resistors

A. Construction and Materials

1. Substrate Types

The substrate is the foundation upon which the thin film resistor is built. Common substrate materials include alumina (Al2O3), silicon, and glass. Each substrate type offers different thermal and electrical properties, influencing the overall performance of the resistor.

2. Thin Film Deposition Techniques

Thin film resistors are manufactured using various deposition techniques, including sputtering, evaporation, and chemical vapor deposition (CVD). These methods allow for the precise control of the film thickness and composition, which are critical for achieving the desired resistance values.

B. Working Principle

1. Resistance Formation

The resistance in thin film resistors is formed by the resistive material deposited on the substrate. The resistance value is determined by the material's resistivity, the thickness of the film, and the geometry of the resistor.

2. Temperature Coefficient of Resistance (TCR)

The temperature coefficient of resistance (TCR) is a measure of how much the resistance changes with temperature. A low TCR is desirable in many applications, as it indicates that the resistor will maintain its performance over a wide temperature range.

III. Key Parameters of Thin Film Resistors

A. Resistance Value

1. Range of Resistance Values

Thin film resistors are available in a wide range of resistance values, typically from a few ohms to several megohms. This versatility allows them to be used in various applications, from precision measurement to signal processing.

2. Tolerance Levels

Tolerance refers to the allowable deviation from the nominal resistance value. Thin film resistors typically offer tighter tolerances (±0.1% to ±1%) compared to other resistor types, making them suitable for high-precision applications.

B. Temperature Coefficient of Resistance (TCR)

1. Definition and Importance

TCR is defined as the change in resistance per degree Celsius change in temperature. It is a critical parameter for applications where temperature variations can affect circuit performance.

2. Typical TCR Values for Mainstream Products

Mainstream thin film resistors typically have TCR values ranging from ±5 ppm/°C to ±50 ppm/°C. Lower TCR values are preferred for high-precision applications, such as instrumentation and aerospace.

C. Power Rating

1. Definition and Measurement

Power rating indicates the maximum power a resistor can dissipate without overheating. It is usually measured in watts (W) and is a crucial parameter for ensuring the reliability of the resistor in a circuit.

2. Impact on Performance and Reliability

Exceeding the power rating can lead to thermal runaway, resulting in resistor failure. Therefore, selecting a resistor with an appropriate power rating for the application is essential for maintaining performance and reliability.

D. Voltage Rating

1. Definition and Importance

Voltage rating is the maximum voltage that can be applied across the resistor without causing breakdown. It is an important consideration in high-voltage applications to prevent damage to the resistor.

2. Breakdown Voltage Considerations

The breakdown voltage of thin film resistors is influenced by the substrate material and the thickness of the resistive layer. Engineers must consider these factors when designing circuits to ensure safe operation.

E. Noise Characteristics

1. Types of Noise in Resistors

Resistors can generate various types of noise, including thermal noise (Johnson noise) and flicker noise (1/f noise). Understanding these noise characteristics is essential for applications where signal integrity is critical.

2. Impact on Circuit Performance

Excessive noise can degrade the performance of sensitive circuits, such as amplifiers and analog-to-digital converters. Therefore, selecting low-noise thin film resistors is crucial for maintaining signal quality.

IV. Performance Characteristics

A. Stability and Reliability

1. Long-term Stability

Thin film resistors are known for their long-term stability, which is essential for applications requiring consistent performance over time. Factors such as humidity, temperature, and mechanical stress can affect stability, so selecting resistors with high stability ratings is important.

2. Environmental Factors Affecting Performance

Environmental conditions, such as temperature fluctuations and exposure to moisture, can impact the performance of thin film resistors. Manufacturers often provide specifications for environmental ratings to guide users in selecting appropriate components.

B. Frequency Response

1. Importance in High-Frequency Applications

In high-frequency applications, the frequency response of a resistor becomes critical. Thin film resistors typically exhibit better frequency response characteristics than other resistor types, making them suitable for RF and microwave applications.

2. Impedance and Reactance Considerations

The impedance of a resistor can change with frequency, leading to reactance effects. Understanding these characteristics is essential for designing circuits that operate effectively at high frequencies.

C. Load Life and Aging Effects

1. Definition and Testing Methods

Load life refers to the ability of a resistor to maintain its performance under continuous load over time. Testing methods, such as accelerated aging tests, are used to evaluate the long-term reliability of thin film resistors.

2. Impact on Resistor Lifespan

Aging effects can lead to changes in resistance value and TCR over time. Selecting resistors with proven load life performance is essential for applications where reliability is critical.

V. Applications of Thin Film Resistors

A. Consumer Electronics

Thin film resistors are widely used in consumer electronics, including smartphones, televisions, and audio equipment, where precision and reliability are paramount.

B. Automotive Industry

In the automotive sector, thin film resistors are employed in various applications, such as engine control units and sensor systems, where high performance and durability are required.

C. Medical Devices

Medical devices, including diagnostic equipment and monitoring systems, rely on thin film resistors for their accuracy and stability, ensuring reliable performance in critical applications.

D. Telecommunications

Thin film resistors are essential in telecommunications equipment, where they help maintain signal integrity and performance in high-speed data transmission.

E. Industrial Automation

In industrial automation, thin film resistors are used in control systems and sensors, providing the precision and reliability needed for efficient operation.

VI. Comparison with Other Resistor Types

A. Thin Film vs. Thick Film Resistors

Thin film resistors offer better precision and stability compared to thick film resistors, making them suitable for high-accuracy applications. However, thick film resistors are often more cost-effective for general-purpose applications.

B. Thin Film vs. Wirewound Resistors

Wirewound resistors provide higher power ratings and are suitable for high-current applications, but they may not offer the same level of precision as thin film resistors. The choice between the two depends on the specific requirements of the application.

C. Advantages and Disadvantages of Thin Film Resistors

Thin film resistors offer several advantages, including high precision, low noise, and excellent temperature stability. However, they may be more expensive than other resistor types, which can be a consideration in cost-sensitive applications.

VII. Future Trends in Thin Film Resistor Technology

A. Innovations in Materials and Manufacturing

Advancements in materials science and manufacturing techniques are driving the development of new thin film resistor technologies. These innovations aim to enhance performance, reduce costs, and improve reliability.

B. Increasing Demand for Miniaturization

As electronic devices continue to shrink in size, the demand for miniaturized components, including thin film resistors, is increasing. Manufacturers are focusing on developing smaller, more efficient resistors to meet this demand.

C. Integration with Other Technologies (e.g., MEMS)

The integration of thin film resistors with micro-electromechanical systems (MEMS) is an emerging trend. This integration allows for the development of compact, multifunctional devices that can perform various tasks in a single package.

VIII. Conclusion

A. Summary of Key Points

Thin film resistors are essential components in modern electronics, offering high precision, stability, and reliability. Understanding their key parameters, such as resistance value, TCR, power rating, and noise characteristics, is crucial for selecting the right resistor for specific applications.

B. Importance of Selecting the Right Thin Film Resistor

Choosing the appropriate thin film resistor can significantly impact the performance and reliability of electronic devices. Engineers must consider various factors, including environmental conditions and application requirements, when making their selection.

C. Final Thoughts on the Future of Thin Film Resistors in Electronics

As technology continues to evolve, thin film resistors will play an increasingly important role in the development of advanced electronic systems. With ongoing innovations in materials and manufacturing, the future of thin film resistors looks promising, ensuring their continued relevance in the ever-changing landscape of electronics.

IX. References

A. Academic Journals

1. "Thin Film Resistors: A Review of Their Properties and Applications," Journal of Electronic Materials.

2. "Advancements in Thin Film Technology for Precision Resistors," IEEE Transactions on Components, Packaging and Manufacturing Technology.

B. Industry Reports

1. "Market Trends in Thin Film Resistors," Electronics Industry Report 2023.

2. "The Future of Resistor Technology," Global Resistor Market Analysis.

C. Manufacturer Specifications and Datasheets

1. Vishay Thin Film Resistor Datasheets.

2. Yageo Thin Film Resistor Product Catalog.

This blog post provides a detailed exploration of mainstream thin film resistor product series parameters, offering valuable insights for engineers and designers in the electronics industry.