What is the mainstream variable resistor production process?

What is the Mainstream Variable Resistor Production Process?

I. Introduction

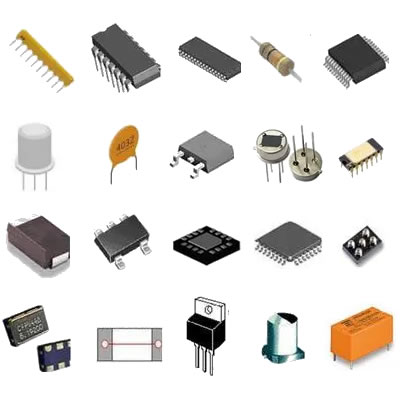

Variable resistors, commonly known as potentiometers or rheostats, are essential components in the world of electronics. They allow for the adjustment of resistance in a circuit, enabling control over voltage and current. This functionality is crucial in various applications, from audio equipment to industrial machinery. Understanding the production process of variable resistors not only sheds light on their importance but also highlights the intricate steps involved in bringing these components to market.

II. Types of Variable Resistors

A. Potentiometers

Potentiometers are three-terminal devices that allow for the adjustment of voltage levels. They consist of a resistive element and a wiper that moves along this element, changing the resistance and, consequently, the voltage output. Common applications include volume controls in audio devices, position sensors, and as adjustable voltage dividers in various electronic circuits.

B. Rheostats

Rheostats are similar to potentiometers but are typically used to control current rather than voltage. They usually have two terminals and are designed to handle higher power levels. Rheostats are commonly found in applications such as light dimmers, motor speed controls, and heating elements.

C. Digital Potentiometers

Digital potentiometers are a modern evolution of traditional variable resistors. They use digital signals to adjust resistance, allowing for precise control and integration with microcontrollers. These devices are widely used in digital audio systems, programmable gain amplifiers, and other applications requiring fine-tuned adjustments.

III. Materials Used in Variable Resistor Production

A. Conductive Materials

The choice of conductive material is critical in determining the performance of variable resistors. Common materials include:

1. **Carbon Composition**: This is a traditional material used in potentiometers. It offers good linearity and is cost-effective, making it suitable for many applications.

2. **Metal Film**: Metal film resistors provide better stability and accuracy compared to carbon. They are often used in high-precision applications due to their low noise and temperature coefficient.

3. **Wirewound**: Wirewound resistors are made by winding a metal wire around a ceramic core. They are capable of handling high power and are often used in rheostats.

B. Insulating Materials

Insulating materials are essential for ensuring the safety and functionality of variable resistors. Common insulating materials include:

1. **Plastics**: Various types of plastics are used for housings and insulation, providing durability and resistance to environmental factors.

2. **Ceramics**: Ceramic materials are often used in high-temperature applications due to their excellent thermal stability and electrical insulation properties.

C. Other Components

In addition to conductive and insulating materials, variable resistors require other components, such as terminals for electrical connections and housings to protect the internal components.

IV. The Production Process

A. Design and Prototyping

The production process begins with design and prototyping. Engineers consider factors such as resistance range, power rating, and physical dimensions. Prototyping techniques, including 3D printing and computer simulations, are employed to create initial models for testing.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing raw materials from suppliers and processing them to meet specific requirements. For example, conductive materials may need to be mixed, shaped, or treated to enhance their properties.

C. Component Fabrication

The fabrication of components is a critical stage in the production process:

1. **Conductive Element Creation**: Depending on the type of variable resistor, the conductive element is manufactured using methods such as screen printing for carbon or depositing metal films onto substrates.

2. **Insulating Element Creation**: Insulating components are produced using molding or extrusion processes, ensuring they meet the necessary specifications for durability and electrical insulation.

D. Assembly

The assembly phase involves combining the various components to create the final product. This includes:

1. **Combining Components**: The conductive and insulating elements are assembled, often requiring precise alignment to ensure proper functionality.

2. **Soldering and Connections**: Electrical connections are made through soldering, ensuring a reliable and conductive path for current flow.

E. Testing and Quality Control

Quality control is paramount in the production of variable resistors. This involves:

1. **Electrical Testing**: Each resistor is tested for its electrical characteristics, including resistance values and tolerance levels.

2. **Mechanical Testing**: Mechanical properties, such as durability and resistance to wear, are also assessed.

3. **Final Quality Assurance**: A final inspection ensures that each product meets industry standards and specifications before it is packaged and shipped.

V. Automation and Technology in Production

A. Role of Automation in Manufacturing

Automation plays a significant role in the production of variable resistors. Automated machinery can perform repetitive tasks with high precision, reducing the risk of human error and increasing production efficiency.

B. Advances in Technology

Recent advances in technology have transformed the manufacturing landscape:

1. **Computer-Aided Design (CAD)**: CAD software allows engineers to create detailed designs and simulations, streamlining the prototyping process.

2. **Robotics in Assembly**: Robotics are increasingly used in assembly lines, enhancing speed and accuracy in the production of variable resistors.

C. Impact on Production Efficiency and Quality

The integration of automation and advanced technologies has led to significant improvements in production efficiency and quality. Manufacturers can produce variable resistors at a lower cost while maintaining high standards of performance and reliability.

VI. Environmental Considerations

A. Sustainable Materials

As environmental concerns grow, manufacturers are exploring sustainable materials for variable resistor production. This includes using recycled materials and developing eco-friendly alternatives to traditional conductive and insulating materials.

B. Waste Management in Production

Effective waste management practices are essential in minimizing the environmental impact of production. This includes recycling scrap materials and implementing processes to reduce waste generation.

C. Energy Consumption

Energy-efficient manufacturing processes are being adopted to reduce the carbon footprint of variable resistor production. This includes optimizing machinery and utilizing renewable energy sources.

VII. Future Trends in Variable Resistor Production

A. Innovations in Materials

The future of variable resistor production may see innovations in materials, such as the development of advanced composites that offer improved performance and sustainability.

B. Smart Variable Resistors

The rise of the Internet of Things (IoT) is driving demand for smart variable resistors that can be controlled remotely and integrated into smart devices, enhancing their functionality and user experience.

C. Market Trends and Demand

As technology continues to evolve, the demand for variable resistors is expected to grow, particularly in sectors such as automotive, consumer electronics, and renewable energy. Manufacturers will need to adapt to these trends to remain competitive.

VIII. Conclusion

In summary, the production process of variable resistors is a complex and multifaceted endeavor that involves careful design, material selection, and quality control. These components play a vital role in modern electronics, enabling precise control over electrical parameters. As technology advances and environmental considerations become more pressing, the future of variable resistor manufacturing looks promising, with opportunities for innovation and growth. Understanding this production process not only highlights the importance of variable resistors but also underscores the intricate craftsmanship that goes into creating these essential electronic components.