When will the measurements of the new resistors be released?

When Will the Measurements of the New Resistors Be Released?

I. Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling current flow and voltage levels. Their importance cannot be overstated, as they are integral to the functionality of virtually all electronic devices, from simple gadgets to complex systems. Accurate measurements of resistors are vital for ensuring reliability and performance in electronic applications. This article aims to explore the timeline and factors influencing the release of new resistor measurements, shedding light on the complexities involved in this seemingly straightforward process.

II. Understanding Resistors

A. Definition and Function of Resistors in Electronics

At its core, a resistor is a passive electrical component that provides resistance to the flow of electric current. By doing so, it helps to manage voltage levels within a circuit, ensuring that components receive the appropriate amount of power. Resistors are essential for protecting sensitive components from excessive current, dividing voltages, and setting bias points in amplifiers.

B. Types of Resistors

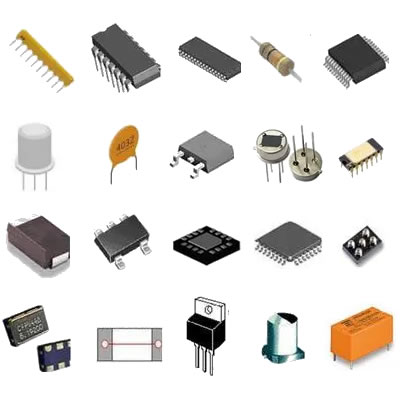

Resistors come in various types, each designed for specific applications. Fixed resistors maintain a constant resistance value, while variable resistors, such as potentiometers, allow for adjustable resistance. Surface mount resistors are compact and designed for automated assembly, making them popular in modern electronics. Understanding the different types of resistors is crucial for selecting the right component for a given application.

C. Importance of Resistance Values and Tolerances

Resistance values, measured in ohms, determine how much current will flow through a resistor at a given voltage. Tolerances indicate the precision of these values, with tighter tolerances being essential for high-performance applications. Accurate measurements of resistance values and tolerances are critical for ensuring that electronic devices function as intended.

III. The Development of New Resistors

A. Innovations in Resistor Technology

The field of resistor technology is continually evolving, driven by the demand for higher performance and miniaturization in electronic devices. Innovations in materials, such as the use of metal film and carbon composition, have led to improved stability and accuracy in resistance values. Additionally, advances in manufacturing processes, including thin-film technology, have enabled the production of resistors with smaller footprints and enhanced performance characteristics.

B. The Role of Research and Development in Resistor Design

Research and development (R&D) play a pivotal role in the design of new resistors. Engineers and scientists work collaboratively to explore new materials and designs that can meet the ever-increasing demands of modern electronics. This R&D process often involves extensive testing and iteration to refine resistor performance and ensure compliance with industry standards.

C. Collaboration Between Manufacturers and Research Institutions

Collaboration between manufacturers and research institutions is essential for driving innovation in resistor technology. By pooling resources and expertise, these entities can accelerate the development of new resistor types and measurement techniques. Such partnerships often lead to breakthroughs that can significantly impact the electronics industry.

IV. Measurement Standards and Protocols

A. Overview of Measurement Standards

Measurement standards, such as those established by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), provide guidelines for testing and measuring resistors. These standards ensure consistency and reliability in measurements, which is crucial for manufacturers and designers alike.

B. Importance of Standardized Measurements for Reliability

Standardized measurements are vital for ensuring that resistors perform as expected in various applications. Without adherence to these standards, discrepancies in resistance values could lead to circuit failures and unreliable performance. Therefore, manufacturers must follow established protocols to guarantee the quality of their products.

C. Common Measurement Techniques Used in Resistor Testing

Several measurement techniques are commonly employed in resistor testing, including four-wire measurements, which minimize the effects of lead resistance, and temperature coefficient measurements, which assess how resistance changes with temperature. These techniques are essential for obtaining accurate and reliable measurements of resistor performance.

V. Factors Influencing Measurement Release Timelines

A. Development and Testing Phases

The timeline for releasing measurements of new resistors is influenced by several factors, starting with the development and testing phases. This process typically begins with prototyping, where initial designs are created and tested for performance. Following this, iterative design and refinement occur, allowing engineers to address any issues and optimize the resistor's characteristics.

B. Regulatory Approvals and Compliance

Once a new resistor design has been finalized, it must undergo regulatory approvals to ensure compliance with industry standards. This process can be time-consuming, as it often involves extensive documentation and testing to demonstrate that the resistor meets all necessary requirements.

C. Market Demand and Competitive Pressures

Market demand also plays a significant role in determining the release timeline for new resistor measurements. Manufacturers must balance the need for timely releases with the desire to ensure that their products meet the highest standards of quality and performance. Competitive pressures can further complicate this process, as companies strive to stay ahead in a rapidly evolving market.

D. Supply Chain Considerations

Supply chain considerations can also impact the release of new resistor measurements. Disruptions in the supply chain, whether due to material shortages or logistical challenges, can delay the production and testing of new resistors. Manufacturers must navigate these challenges to ensure that they can deliver their products on time.

VI. Anticipated Timeline for Release

A. Typical Timelines for Resistor Development and Measurement Release

The typical timeline for the development and measurement release of new resistors can vary widely depending on the complexity of the design and the factors mentioned above. Generally, the process can take anywhere from several months to a few years, with more advanced designs requiring longer development times.

B. Case Studies of Previous Resistor Releases

Examining case studies of previous resistor releases can provide valuable insights into the timelines involved. For instance, the introduction of metal film resistors in the 1970s involved extensive R&D and testing, ultimately leading to a significant improvement in performance and reliability. Such historical examples highlight the importance of thorough testing and compliance in the release process.

C. Current Industry Trends and Projections

Current industry trends indicate a growing demand for high-precision resistors, particularly in applications such as automotive electronics and telecommunications. As manufacturers respond to these trends, the timelines for releasing new resistor measurements may continue to evolve, with an emphasis on rapid development and testing cycles.

VII. Implications of Delayed Measurements

A. Impact on Manufacturers and Designers

Delays in the release of new resistor measurements can have significant implications for manufacturers and designers. Without access to accurate measurements, designers may struggle to create reliable circuits, leading to potential product failures and increased costs.

B. Consequences for Product Development Cycles

The consequences of delayed measurements extend to product development cycles as well. Manufacturers may find themselves unable to meet market demands or launch new products on schedule, resulting in lost revenue and diminished competitiveness.

C. Potential Effects on the Electronics Market

The broader electronics market can also be affected by delays in resistor measurement releases. As manufacturers grapple with these challenges, consumers may experience longer wait times for new products, ultimately impacting the overall growth and innovation within the industry.

VIII. Conclusion

In conclusion, the release of measurements for new resistors is a complex process influenced by various factors, including development timelines, regulatory approvals, market demand, and supply chain considerations. Accurate resistor measurements are essential for ensuring the reliability and performance of electronic devices, making it crucial for stakeholders to stay informed about developments in this field. As technology continues to advance, the future of resistor technology and measurement releases holds promise, with ongoing innovations likely to shape the landscape of electronics for years to come.

IX. References

1. International Electrotechnical Commission (IEC) Standards

2. American National Standards Institute (ANSI) Guidelines

3. Academic papers on resistor technology and measurement techniques

4. Industry reports on trends in electronic components and resistors

5. Additional resources for further reading on resistor technology and measurement standards

This blog post provides a comprehensive overview of the factors influencing the release of new resistor measurements, emphasizing the importance of accuracy and reliability in the electronics industry. By understanding these dynamics, stakeholders can better navigate the complexities of resistor development and measurement.