What are the advantages of ceramic resistor products?

What are the Advantages of Ceramic Resistor Products?

I. Introduction

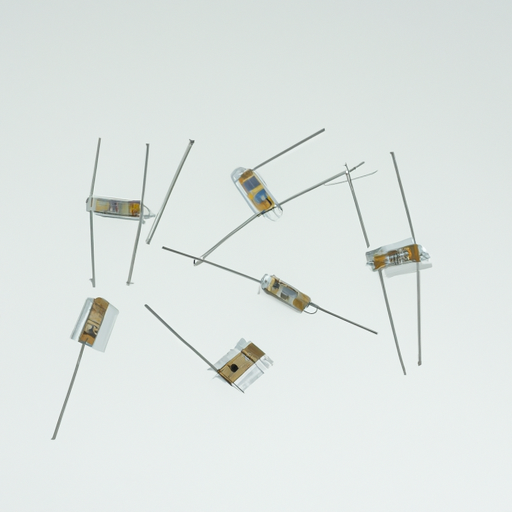

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, ceramic resistors stand out due to their unique properties and advantages. Ceramic resistors are made from a combination of ceramic materials and conductive elements, offering a range of benefits that make them suitable for various applications. This article aims to explore the advantages of ceramic resistor products, their composition, manufacturing processes, applications, and how they compare to other resistor types.

II. Composition and Manufacturing of Ceramic Resistors

A. Materials Used in Ceramic Resistors

Ceramic resistors are primarily composed of ceramic materials, which provide excellent thermal and electrical properties. The most common types of ceramics used include alumina and zirconia. Alumina, known for its high thermal stability and electrical insulation, is often the material of choice for many ceramic resistors. Zirconia, on the other hand, offers superior mechanical strength and is used in applications requiring enhanced durability.

In addition to ceramics, conductive materials such as metal oxides are incorporated into the resistor's composition. These materials are essential for creating the resistive element that determines the resistor's value.

B. Manufacturing Processes

The manufacturing of ceramic resistors involves several key processes, including sintering and printing techniques. Sintering is a process where ceramic powders are heated to a temperature below their melting point, causing the particles to bond together and form a solid structure. This process enhances the mechanical strength and thermal stability of the resistor.

Printing techniques, such as screen printing or inkjet printing, are used to apply the resistive material onto the ceramic substrate. These methods allow for precise control over the resistor's dimensions and resistance values.

C. Quality Control Measures

Quality control is critical in the production of ceramic resistors to ensure their reliability and performance. Manufacturers implement rigorous testing procedures, including electrical testing, thermal cycling, and mechanical stress tests, to verify that the resistors meet industry standards and specifications.

III. Key Advantages of Ceramic Resistor Products

A. High Thermal Stability

One of the most significant advantages of ceramic resistors is their high thermal stability. They can withstand extreme temperature fluctuations without compromising their performance. This characteristic makes them ideal for applications in high-temperature environments, such as automotive and industrial settings, where other resistor types may fail.

B. Excellent Electrical Insulation

Ceramic resistors offer excellent electrical insulation properties, resulting in low leakage current and high dielectric strength. This feature is particularly important in sensitive electronic applications where maintaining signal integrity is crucial. The ability to prevent unwanted current flow enhances the overall performance and reliability of electronic circuits.

C. Superior Power Handling Capability

Ceramic resistors are known for their superior power handling capabilities. They can dissipate heat effectively, allowing them to operate at higher power levels without overheating. This advantage is especially beneficial in power electronics, where resistors are subjected to significant thermal stress. Compared to other resistor types, ceramic resistors can handle higher power loads, making them a preferred choice in demanding applications.

D. Chemical Resistance

Another notable advantage of ceramic resistors is their resistance to chemical corrosion. They can withstand exposure to harsh chemicals and environments, ensuring longevity and reliability in applications where other materials might degrade. This characteristic is particularly valuable in industrial settings, where resistors may be exposed to corrosive substances.

E. Mechanical Strength and Durability

Ceramic resistors exhibit exceptional mechanical strength and durability. They are resistant to physical stress and impact, making them suitable for applications in rugged environments. This durability ensures that ceramic resistors maintain their performance over time, even in challenging conditions.

F. Low Noise Characteristics

In sensitive electronic applications, noise can significantly impact performance. Ceramic resistors are known for their low noise characteristics, which is a crucial advantage in applications such as audio equipment and precision measurement devices. When compared to carbon and metal film resistors, ceramic resistors produce less electrical noise, contributing to cleaner signal transmission.

G. Versatility in Design

Ceramic resistors offer versatility in design, allowing for customization options to meet specific application requirements. They are available in various shapes and sizes, making them suitable for a wide range of electronic devices. This adaptability enables engineers to incorporate ceramic resistors into diverse circuit designs without compromising performance.

IV. Applications of Ceramic Resistors

A. Industrial Applications

Ceramic resistors are widely used in industrial applications, particularly in power electronics. They are essential components in power supplies, motor drives, and other high-power devices. Additionally, the automotive industry relies on ceramic resistors for various applications, including engine control units and power management systems.

B. Consumer Electronics

In the realm of consumer electronics, ceramic resistors are found in home appliances, personal devices, and audio equipment. Their low noise characteristics and thermal stability make them ideal for applications where performance and reliability are paramount.

C. Medical Equipment

Ceramic resistors play a vital role in medical equipment, including diagnostic devices and monitoring systems. The reliability and precision of ceramic resistors are critical in ensuring accurate measurements and safe operation in medical applications.

D. Aerospace and Defense

In aerospace and defense applications, where reliability is non-negotiable, ceramic resistors are preferred for their high-performance capabilities. They are used in critical systems that require consistent performance under extreme conditions, making them essential for mission-critical applications.

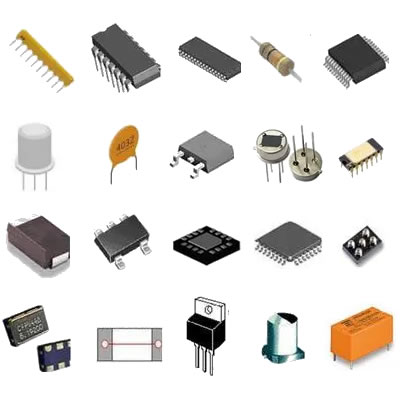

V. Comparison with Other Resistor Types

A. Carbon Resistors

Carbon resistors are known for their low cost and simplicity. However, they have limitations in terms of thermal stability and power handling compared to ceramic resistors. While carbon resistors may be suitable for low-power applications, they are not ideal for high-temperature or high-power environments.

B. Metal Film Resistors

Metal film resistors offer better precision and stability than carbon resistors but may not match the thermal stability and power handling capabilities of ceramic resistors. They are often used in applications requiring high accuracy, but ceramic resistors are preferred in high-power scenarios.

C. Wirewound Resistors

Wirewound resistors are known for their high power handling and precision. However, they can be bulkier and less versatile than ceramic resistors. In applications where space is a concern, ceramic resistors may be the better choice.

D. Summary of When to Choose Ceramic Resistors Over Others

When selecting resistors for specific applications, engineers should consider factors such as thermal stability, power handling, noise characteristics, and environmental conditions. Ceramic resistors are often the best choice for high-power, high-temperature, and corrosive environments, while other resistor types may be more suitable for low-power or cost-sensitive applications.

VI. Future Trends in Ceramic Resistor Technology

A. Innovations in Materials and Manufacturing

The future of ceramic resistor technology is promising, with ongoing innovations in materials and manufacturing processes. Researchers are exploring new ceramic compositions and advanced manufacturing techniques to enhance performance and reduce costs.

B. Increasing Demand in Emerging Technologies

As technology continues to evolve, the demand for high-performance components like ceramic resistors is expected to grow. Emerging technologies, such as electric vehicles and renewable energy systems, will drive the need for reliable and efficient resistors.

C. Environmental Considerations and Sustainability

Sustainability is becoming increasingly important in the electronics industry. Manufacturers are focusing on developing eco-friendly materials and processes for ceramic resistors, aligning with global efforts to reduce environmental impact.

VII. Conclusion

In summary, ceramic resistors offer a range of advantages that make them a preferred choice in various applications. Their high thermal stability, excellent electrical insulation, superior power handling capability, chemical resistance, mechanical strength, low noise characteristics, and design versatility set them apart from other resistor types. As technology advances, the demand for ceramic resistors is likely to increase, making them an essential component in the future of electronics. Selecting the right resistor for specific applications is crucial, and understanding the benefits of ceramic resistors can help engineers make informed decisions.

VIII. References

1. "Ceramic Resistors: Properties and Applications." Journal of Electronic Materials.

2. "Advancements in Resistor Technology." IEEE Transactions on Components, Packaging and Manufacturing Technology.

3. "The Role of Resistors in Electronic Circuits." Electronics Weekly.

4. "Sustainability in Electronics Manufacturing." Environmental Science & Technology.

This blog post provides a comprehensive overview of the advantages of ceramic resistor products, highlighting their unique properties and applications in various industries.