What product types do integrated circuit boards include?

What Product Types Do Integrated Circuit Boards Include?

I. Introduction

Integrated Circuit Boards (ICBs) are the backbone of modern electronics, serving as the foundation for a wide array of devices that we use daily. From smartphones to medical equipment, ICBs play a crucial role in ensuring that electronic components function seamlessly together. This article aims to explore the various product types that integrated circuit boards encompass, highlighting their significance across different industries and the innovations shaping their future.

II. Understanding Integrated Circuit Boards

A. Definition and Functionality

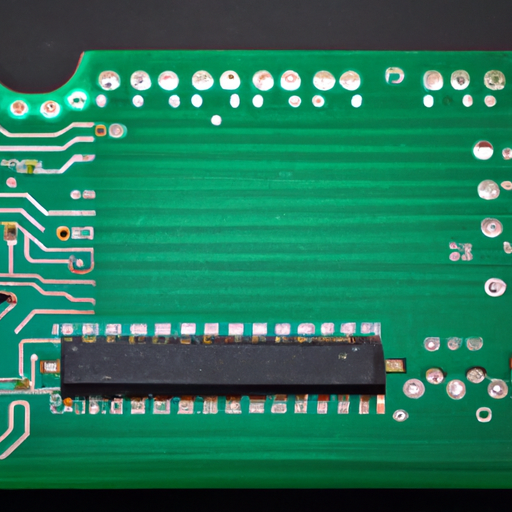

Integrated circuits (ICs) are miniaturized electronic circuits that combine multiple components, such as transistors, resistors, and capacitors, into a single chip. These chips are mounted on circuit boards, which provide the necessary connections and support for the components. Circuit boards serve as the platform that allows ICs to communicate with each other and with external devices, making them essential for the operation of electronic devices.

B. Types of Integrated Circuit Boards

There are several types of integrated circuit boards, each designed for specific applications:

1. **Single-Sided Circuit Boards**: These boards have components mounted on one side only, making them simpler and more cost-effective. They are commonly used in low-density applications.

2. **Double-Sided Circuit Boards**: These boards have components on both sides, allowing for a higher density of components and more complex circuitry. They are widely used in consumer electronics.

3. **Multi-Layer Circuit Boards**: These boards consist of multiple layers of circuitry, allowing for even greater complexity and functionality. They are essential for high-performance applications, such as computers and advanced communication devices.

III. Product Types of Integrated Circuit Boards

Integrated circuit boards are found in a diverse range of products across various industries. Here are some key categories:

A. Consumer Electronics

1. **Smartphones and Tablets**: ICBs are integral to the functionality of smartphones and tablets, housing the processors, memory, and other essential components that enable communication, multimedia, and applications.

2. **Laptops and Desktops**: These devices rely on multi-layer circuit boards to support powerful processors, graphics cards, and storage solutions, allowing for complex computing tasks.

3. **Televisions and Home Entertainment Systems**: ICBs in these products manage video processing, audio output, and connectivity features, enhancing the overall user experience.

B. Industrial Applications

1. **Automation and Control Systems**: ICBs are used in industrial automation to control machinery and processes, improving efficiency and safety in manufacturing environments.

2. **Robotics**: Integrated circuit boards are crucial for the operation of robotic systems, enabling precise control and communication between various components.

3. **Medical Devices**: ICBs are found in a wide range of medical equipment, from diagnostic machines to patient monitoring systems, ensuring accurate data processing and reliability.

C. Automotive Industry

1. **Engine Control Units (ECUs)**: ICBs are essential for managing engine performance, fuel efficiency, and emissions in modern vehicles.

2. **Infotainment Systems**: These systems rely on integrated circuit boards to provide navigation, entertainment, and connectivity features, enhancing the driving experience.

3. **Advanced Driver-Assistance Systems (ADAS)**: ICBs play a critical role in safety features such as adaptive cruise control, lane-keeping assistance, and collision avoidance systems.

D. Telecommunications

1. **Networking Equipment**: ICBs are used in routers, switches, and other networking devices to facilitate data transmission and connectivity.

2. **Base Stations**: Integrated circuit boards are essential for the operation of cellular base stations, enabling wireless communication.

3. **Satellite Communication Systems**: ICBs are used in satellite technology to manage signal processing and communication with ground stations.

E. Aerospace and Defense

1. **Avionics Systems**: ICBs are critical for navigation, communication, and control systems in aircraft, ensuring safety and reliability.

2. **Military Communication Devices**: Integrated circuit boards are used in secure communication systems, enabling effective coordination in defense operations.

3. **Navigation Systems**: ICBs are essential for GPS and other navigation technologies, providing accurate positioning and timing information.

F. Internet of Things (IoT)

1. **Smart Home Devices**: ICBs are found in smart thermostats, security systems, and other connected devices, enabling automation and remote control.

2. **Wearable Technology**: Integrated circuit boards power fitness trackers, smartwatches, and health monitoring devices, providing real-time data and connectivity.

3. **Industrial IoT Solutions**: ICBs are used in sensors and devices that monitor and control industrial processes, enhancing efficiency and data collection.

IV. Key Components of Integrated Circuit Boards

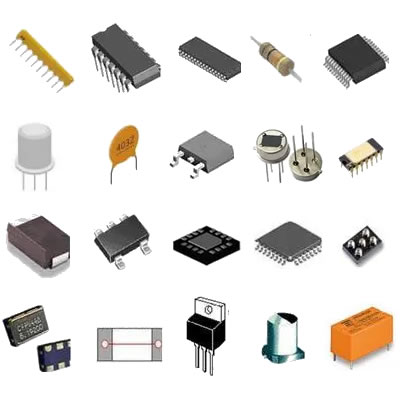

Integrated circuit boards consist of several key components that work together to ensure functionality:

A. Resistors

Resistors limit the flow of electrical current, protecting sensitive components and ensuring proper operation.

B. Capacitors

Capacitors store and release electrical energy, helping to stabilize voltage and filter signals.

C. Inductors

Inductors store energy in a magnetic field, playing a crucial role in filtering and energy management.

D. Microcontrollers and Microprocessors

These components serve as the "brains" of the circuit board, executing instructions and processing data.

E. Connectors and Interfaces

Connectors and interfaces enable communication between the circuit board and external devices, facilitating data transfer and power supply.

V. Manufacturing Processes of Integrated Circuit Boards

The manufacturing of integrated circuit boards involves several key processes:

A. Design and Prototyping

The design phase includes creating schematics and layouts for the circuit board, often using specialized software. Prototyping allows for testing and refinement before mass production.

B. Material Selection

Choosing the right materials is crucial for performance and reliability. Common materials include fiberglass, epoxy resin, and copper for conductive pathways.

C. Fabrication Techniques

1. **Etching**: This process removes unwanted copper from the board to create the desired circuit pattern.

2. **Soldering**: Soldering is used to attach components to the board, ensuring electrical connections.

3. **Assembly**: The final assembly involves placing components on the board and ensuring proper alignment and connections.

D. Testing and Quality Assurance

Testing is essential to ensure that the circuit board functions correctly and meets industry standards. Quality assurance processes help identify and rectify any defects.

VI. Trends and Innovations in Integrated Circuit Boards

The field of integrated circuit boards is constantly evolving, with several trends and innovations shaping the future:

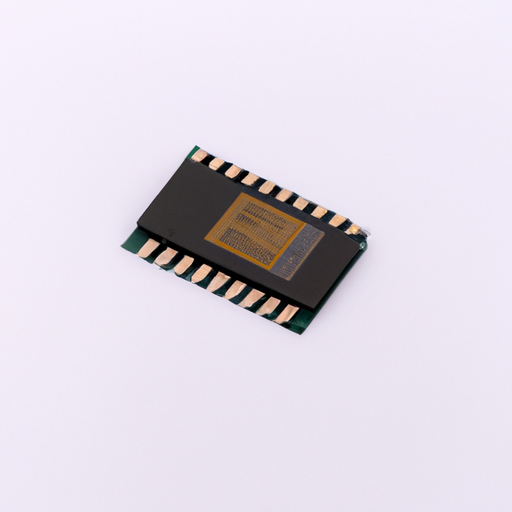

A. Miniaturization and High-Density Interconnects

As electronic devices become smaller and more powerful, the demand for miniaturized circuit boards with high-density interconnects is increasing. This trend allows for more components to be packed into smaller spaces.

B. Flexible and Printed Circuit Boards

Flexible circuit boards are gaining popularity due to their lightweight and adaptable nature, making them ideal for wearable technology and compact devices.

C. Advances in Materials and Technologies

New materials and manufacturing techniques are being developed to enhance performance, reduce costs, and improve sustainability in circuit board production.

D. Environmental Considerations and Sustainability

As the electronics industry faces increasing scrutiny over environmental impact, manufacturers are exploring sustainable practices, such as using eco-friendly materials and reducing waste.

VII. Conclusion

Integrated circuit boards are a fundamental component of modern electronics, enabling a wide range of products across various industries. From consumer electronics to aerospace applications, ICBs play a crucial role in ensuring functionality and performance. As technology continues to advance, the future of integrated circuit boards looks promising, with innovations in design, materials, and manufacturing processes paving the way for even more sophisticated applications. Understanding the significance of ICBs is essential for anyone interested in the evolving landscape of electronics and technology.

VIII. References

A comprehensive list of academic papers, articles, and resources for further reading would typically follow here, providing readers with additional information on integrated circuit boards and their applications.