What are the purchasing models of the latest integrated circuit equipment components?

Purchasing Models of the Latest Integrated Circuit Equipment Components

I. Introduction

Integrated circuits (ICs) are the backbone of modern electronics, powering everything from smartphones to sophisticated computing systems. The equipment used to manufacture, test, and package these circuits is critical to the semiconductor industry. As technology evolves, so too do the purchasing models for integrated circuit equipment components. Understanding these models is essential for companies looking to optimize their procurement processes and stay competitive in a rapidly changing market.

II. Understanding Integrated Circuit Equipment Components

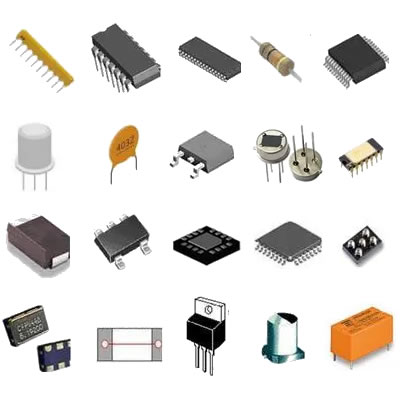

A. Types of Integrated Circuit Equipment

1. **Fabrication Equipment**: This includes tools and machines used in the manufacturing process of ICs, such as photolithography systems, etchers, and deposition equipment. These tools are essential for creating the intricate patterns and structures that define modern ICs.

2. **Testing Equipment**: After fabrication, ICs must be tested to ensure they function correctly. Testing equipment includes automated test equipment (ATE) that evaluates the performance and reliability of ICs before they are packaged and shipped.

3. **Packaging Equipment**: Once ICs are tested, they need to be packaged for protection and integration into electronic devices. Packaging equipment includes machines that encapsulate the ICs in protective materials and prepare them for shipment.

B. Key Players in the IC Equipment Market

1. **Manufacturers**: These are companies that design and produce IC equipment. Major players include Applied Materials, ASML, and Lam Research.

2. **Suppliers**: Suppliers provide the raw materials and components necessary for manufacturing IC equipment, such as silicon wafers, chemicals, and specialized parts.

3. **Distributors**: Distributors play a crucial role in the supply chain by connecting manufacturers with end-users, ensuring that equipment reaches the right customers in a timely manner.

III. Traditional Purchasing Models

A. Direct Purchasing

1. **Description and Process**: Direct purchasing involves companies buying equipment directly from manufacturers. This model typically includes negotiations on price, delivery, and warranty terms.

2. **Advantages and Disadvantages**: The primary advantage of direct purchasing is the potential for cost savings and better control over the procurement process. However, it can also lead to longer lead times and less flexibility in adapting to changing needs.

B. Request for Proposal (RFP)

1. **Description and Process**: An RFP is a formal document that solicits proposals from suppliers for specific equipment needs. Companies outline their requirements, and suppliers respond with detailed proposals.

2. **Advantages and Disadvantages**: RFPs can lead to competitive pricing and innovative solutions, but they can also be time-consuming and may not always yield the best results if suppliers do not fully understand the company's needs.

C. Long-term Contracts

1. **Description and Process**: Long-term contracts involve agreements between companies and suppliers for the supply of equipment over an extended period. These contracts often include fixed pricing and guaranteed supply.

2. **Advantages and Disadvantages**: The main advantage is stability in pricing and supply, which can help companies plan their budgets. However, these contracts can limit flexibility and may not adapt well to market changes.

IV. Emerging Purchasing Models

A. E-Procurement

1. **Definition and Overview**: E-procurement refers to the use of digital platforms to facilitate the purchasing process. This model allows companies to streamline procurement, reduce costs, and improve efficiency.

2. **Benefits of E-Procurement in the IC Industry**: E-procurement can enhance transparency, reduce paperwork, and enable better tracking of orders and inventory. It also allows for easier comparison of suppliers and pricing.

B. Collaborative Purchasing

1. **Description and Process**: Collaborative purchasing involves multiple companies coming together to purchase equipment collectively. This model can lead to bulk purchasing discounts and shared resources.

2. **Advantages and Disadvantages**: The primary advantage is cost savings through economies of scale. However, it requires strong collaboration and trust among participating companies, which can be challenging to establish.

C. Just-in-Time (JIT) Purchasing

1. **Definition and Overview**: JIT purchasing is a strategy where companies order equipment and materials only as needed, minimizing inventory costs and reducing waste.

2. **Benefits and Challenges**: JIT can lead to significant cost savings and increased efficiency. However, it also requires precise coordination with suppliers and can be risky if supply chain disruptions occur.

V. Factors Influencing Purchasing Decisions

A. Technological Advancements

Rapid advancements in technology can influence purchasing decisions, as companies must stay updated with the latest equipment to remain competitive. New technologies may require different types of equipment, prompting companies to reassess their purchasing strategies.

B. Market Demand and Supply Dynamics

The balance between supply and demand in the IC market can significantly impact purchasing decisions. Fluctuations in demand can lead to changes in pricing and availability, necessitating agile purchasing strategies.

C. Cost Considerations

Cost remains a critical factor in purchasing decisions. Companies must evaluate not only the initial purchase price but also the total cost of ownership, including maintenance, training, and potential downtime.

D. Supplier Relationships and Reliability

Strong relationships with reliable suppliers can enhance purchasing decisions. Companies often prefer to work with suppliers who have a proven track record of delivering quality equipment on time.

VI. Case Studies

A. Successful Implementation of Traditional Models

Many established semiconductor companies have successfully utilized traditional purchasing models, such as long-term contracts, to secure stable pricing and supply. For instance, a leading chip manufacturer entered into a long-term agreement with a fabrication equipment supplier, ensuring consistent access to cutting-edge technology while managing costs effectively.

B. Innovative Use of Emerging Models

A notable example of innovative purchasing is a collaborative purchasing initiative among several tech firms that pooled resources to acquire advanced testing equipment. This approach not only reduced costs but also fostered partnerships that led to shared insights and innovations.

C. Lessons Learned from Industry Leaders

Industry leaders emphasize the importance of flexibility in purchasing models. Companies that adapt their strategies to changing market conditions and technological advancements are better positioned to succeed.

VII. Future Trends in Purchasing Models

A. Impact of Artificial Intelligence and Automation

The integration of AI and automation in procurement processes is expected to revolutionize purchasing models. AI can analyze vast amounts of data to predict market trends, optimize inventory levels, and enhance supplier selection.

B. Sustainability and Ethical Sourcing

As sustainability becomes a priority for many companies, purchasing models will increasingly focus on ethical sourcing and environmentally friendly practices. Companies will seek suppliers that align with their sustainability goals.

C. Globalization and Supply Chain Considerations

Globalization continues to shape the IC equipment market, with companies sourcing materials and equipment from around the world. This trend necessitates a keen understanding of international supply chains and the ability to navigate potential disruptions.

VIII. Conclusion

In conclusion, the purchasing models for integrated circuit equipment components are evolving in response to technological advancements, market dynamics, and changing business needs. Companies must remain agile and adaptable, leveraging both traditional and emerging models to optimize their procurement processes. As the industry continues to evolve, staying informed about trends and best practices will be crucial for success in the competitive landscape of integrated circuit manufacturing.

IX. References

A comprehensive list of academic journals, industry reports, and expert interviews would be included here to support the insights and information presented in this blog post.

---

This blog post provides a detailed exploration of the purchasing models for integrated circuit equipment components, highlighting both traditional and emerging strategies while considering the factors that influence purchasing decisions and future trends in the industry.